Forum Replies Created

-

AuthorPosts

-

HostgatorMember

From my reading of your problem, it looks like you have more of a problem with your transmission than you may think. The fact is that a flush and clean of your transmission will neither do any harm nor will it do much good, either.

From the sound things, it sounds as if your transmission is on its last legs and needs to be replaced with a rebuilt. The cost will be about $3,400 or so.

The reason I think your transmission is gone is simple. The VW is hanging in gear for too long and then going into gear. You also said there’s a fluid leak and there’s a burned smell.

The leak is troubling as it could mean that an input or output shaft bearing is gone and it is leaking transmission fluid. It could also indicate that the gasketing material along the transmission pan is leaking and that the pan cover needs to be cleaned and the gasket material must be replaced. Actually, the leaking pan cover is the lesser of your problems as the output or input shaft problem could indicate that there’s a problem with the shaft itself which means that the transmission will need a tear down and the shafts will have to be repaired or replaced.

You also indicated there was a burned smell which is troubling because it indicates there is overheating going on within the transmission. The overheating is usually caused by metal-on-metal contact within the transmission. If there is metal-on-metal contact then it’s only a matter of time before there is a significant failure within the case itself.

The reason you are smelling something is burned it because the fluid itself is organic and will burn when it is heated. When it is heated, by the way, it loses not only its viscosity, but also its lubricating and heat-carrying capacity. When that happens, it usually means there is more damage being caused because the fluid is no longer doing its job.

However, you look at it, your only move, at this point, is a rebuilt transmission.

Need a replacement transmission? Quality transmissions are hard to find. Free estimate to your email.HostgatorMemberThis could be caused by three things.

The first could be a torque converter problem. It may be that the that something is causing the flow from the converter to the impeller to miss by just a bit. The problem could be a vane on the converter or on the impeller.

The second could be a problem with the bands/clutches. If the bands are slipping slightly then it is possible that your transmission could be delayed going into drive. It could be the clutches or the bands. Usually, they break down in pairs so that if one goes then the other is sure to follow. So, if clutches or bands are slipping, then, your pickup will have a slipping upshift and delay.

Finally — and the one thing that I think is probably the issue causing the problem — your transmission fluid could be low. If the fluid is down by a quart or so, it means that the components in the transmission are working harder to get the proper pressure to have things work properly.

I think that if you check the fluid you will find it down. I’d suggest obtaining a quart or so to replace whatever may be missing and carefully adding it to refill things. I think that once you’ve refilled things, you’ll find the problem is fixed.

One other place to look is the filter. It could be that the transmission filter is plugged or nearly plugged and is slowing things up. To replace it, you’ll have to drain the fluid from the case, drop the pan cover (be sure there’s a bucket underneath to catch the quart of so of fluid that never gets drained properly), locate and replace the filter (and screen, too, if it needs it).

HostgatorMemberThanks! Just off the top of my head right now, can you check the transmission fluid level? I know you probably have had this done, but, I am wondering if your transmission might not have sprung a pinhole leak somewhere, maybe along a seam that should have been sealed with and RTV-like substance (that’s the stuff they put around sinks and things exposed to the weather to keep water out permanently). If your transmission is trying to spin up, it’s entirely possible that the torque converter may just be uncovered and trying to send transmission fluid to the impeller, but it is just not working.

It’s quick and I can give you the steps if you need them. It’s just a thought for a late night.

HostgatorMemberOkay, since you know very little about cars, maybe it’s time to learn a bit, right? Let’s start with the transmission fluid level. Your Chev is 12 years old and I don’t know how faithful you are to having it serviced at the recommended intervals, so I will assume you handle things like many people — you want until something breaks, right? By the point that something breaks, your expenses become quite high, sometimes, to the brink of unaffordability for many people.

With that said, here’s a thought. Read the owner’s manual before you go any further. It will show you when your Chevrolet’s transmission should have been serviced. If you had followed those guidelines, the chances are excellent that we wouldn’t be having this conversation. Okay, it may seem like you are locking the barn door after the horses have escaped, but, that’s not the case at all. By reading the manual now, you will be avoiding similar occurrences in the future, especially if you purchase a later-model or new vehicle.

The first thing to do next is check the transmission fluid level. It is very possible that the level is down so far that your tranny’s torque converter — the device that sets things in motion within the automatic — may honestly be above the transmission fluid so that if there is any movement at all, there’s not fluid movement. Without transmission fluid moving from the torque converter, the turbine blades of the impeller never spin and the current that is supposed to be set up in the transmission so that everything works correctly, won’t happen and your car won’t move.

So, you can see just how important a simple thing like checking the transmission fluid is. If you don’t do it regularly over time, it is possible for the fluid to evaporate or “burn” away due to heat losses. As the fluid is an organic, it is subject to heat stress at a fairly low temperature so it is possible for your transmission to lose its fluid even without the usual suspects — leaks, broken seals, clogged filters, overfilling and/or underfilling.

Checking your fluid level is easy. Take the following steps:

- Either set the parking brake and run your car for 20 minutes to heat the transmission fluid or drive your car for 20 minutes, covering at least five miles so the fluid comes up to proper temperature.

- If you opt for allowing your car to idle and run, you can use this time to locate the transmission fluid dipstick. It may have an attention-getting color on the handle so you will see it. If you have driven your car, then, when you park, find the dipstick.

- Grab the top of the dipstick, making certain that you don’t burn yourself on the hot engine, and withdraw it from the filler neck.

- Wipe the dipstick with a clean cloth and reinsert it in the filler neck, sliding it in as far as it will travel.

- Withdraw the dipstick and check the fluid level. It should be between the FILL and FULL lines.

- Obtain a couple of quarts of the proper transmission fluid for your brand.

- Pouring carefully — use a small, clean funnel in the filler neck — add transmission fluid a bit at a time and then recheck the level. Small increments should enable you to ensure that your transmission fluid remain in between the lines.

- Replace the dipstick and you are finished.

Your next step with the fluid refilled is to check for proper operation. I suspect that the refill might just do it. However, if it does not, there are some other areas that you should have checked immediately.

Get your Chevy to a good independent transmission shop and ask the technician to check the transmission solenoids. On your transmission, there will likely be two, one on the outside of the valve body and the other on the inside. The solenoids are key to proper operation because they set the gear that you have selected with the gearshift. If one or both of them have failed — they can only last so long; 12 years is a long time — then your transmission won’t work.

To find out of the solenoids have failed, have the technician run a diagnostic with an OBD-II scanner and the proper software (each automaker has its own). The result codes that tell you what is wrong are stored in the engine’s ECM or engine control module memory. Get a printout of the error codes that may have been generated and follow the results. That should enable your technician to repair the tranny.

As you can see, this list is by no means comprehensive. It would take more space than I have here to answer your question. Don’t be shy about asking me specific follow up questions that might arise from the diagnostic as I do like to help. If I don’t know the answer, I know where to find it and will get it to you quickly.

HostgatorMemberThis sounds like a case where you changed all of the right parts, but the electronics may not have caught up. Let’s look at it logically. Since you changed all of the key mechanical parts in the proper sequence and reset it properly, the only things that might be out of kilter, causing your problem, would be the electronics.

There are a few electronic things that can cause this problem beyond the obvious cause, the solenoids. The reason that the problem wouldn’t be the solenoids, in your case, is that you replaced them, so you are ahead of the game, here.

However, it’s not to say that there’s not another piece of electronic gear that’s not working correctly. For example, the Engine Control Module (ECM) or the microcomputer that is controlling the engine, drivetrain and everything else, might be bad. And, then there’s the Transmission Control Module (TCM) or the microcomputer that controls the transmission specifically. It may also be failing, as well. Or, it might be a sensor or set of sensors such as the Throttle Position Sensor (TPS) or the Mass Air Flow (MAF) sensor that might be going or gone.

As you can see, there’s a whole realm that might be impacting your transmission, not just the mechanical parts that you have already switched out.

Here’s my thinking on this: Have a technician throw an OBD-II diagnostic scanner on your car and run a diagnostic of the vehicle, watching for any codes that might relate to the transmission or the sensor suite that is connected to it. I think, quite frankly, that the scanner should be able to catch any error codes relating to transmission. Those codes, by the way, are also stored in the ECM’s memory, so if you think you missed any codes, they will be available for reading, anyway.

Check out the electronics and error codes and I think you’ll find the answer to your problem right there. The good news is that, compared to transmission mechanicals, electronics are far less expensive to replace. And, you don’t have to strip down the tranny to get to them, for the most part. I hope this helps.

HostgatorMemberThis sounds like a case where you changed all of the right parts, but the electronics may not have caught up. Let’s look at it logically. Since you changed all of the key mechanical parts in the proper sequence and reset it properly, the only things that might be out of kilter, causing your problem, would be the electronics.

There are a few electronic things that can cause this problem beyond the obvious cause, the solenoids. The reason that the problem wouldn’t be the solenoids, in your case, is that you replaced them, so you are ahead of the game, here.

However, it’s not to say that there’s not another piece of electronic gear that’s not working correctly. For example, the Engine Control Module (ECM) or the microcomputer that is controlling the engine, drivetrain and everything else, might be bad. And, then there’s the Transmission Control Module (TCM) or the microcomputer that controls the transmission specifically. It may also be failing, as well. Or, it might be a sensor or set of sensors such as the Throttle Position Sensor (TPS) or the Mass Air Flow (MAF) sensor that might be going or gone.

As you can see, there’s a whole realm that might be impacting your transmission, not just the mechanical parts that you have already switched out.

Here’s my thinking on this: Have a technician throw an OBD-II diagnostic scanner on your car and run a diagnostic of the vehicle, watching for any codes that might relate to the transmission or the sensor suite that is connected to it. I think, quite frankly, that the scanner should be able to catch any error codes relating to transmission. Those codes, by the way, are also stored in the ECM’s memory, so if you think you missed any codes, they will be available for reading, anyway.

Check out the electronics and error codes and I think you’ll find the answer to your problem right there. The good news is that, compared to transmission mechanicals, electronics are far less expensive to replace. And, you don’t have to strip down the tranny to get to them, for the most part. I hope this helps.

September 13, 2016 at 2:54 pm in reply to: I have a 2003 Chevy silverado 1500 Standard 5 speed transmission #6917HostgatorMemberThe guys who told you the throw-out bearing is on the way out were the ones who would get my business! When you depress the clutch, the throw-out bearing is set into motion. Its action separates the clutch from the flywheel pressure plate so that the direct connection between the engine and transmission is stopped.

As it wears, the throw-out bearing’s action can become “sloppy.” In other words, there is too much “slop” or play in the bearing action. The result is that it can jounce or bang when you depress the clutch so that instead of being nice and smooth, the action can become jerky and clunking can result.

I can see where you might think that the motor mounts are too blame, honestly. Because of uneven wear in the mounts, it is quite possible for the engine to clunk when you shift as the engine torques around on the mounts. Normally, the packing around each mount is supposed to absorb any jouncing so that its operation remains smooth, at all times.

Replacing the throwout bearing should cost you about $500 with all labor included.

If you would, could you let me know the outcome as I am always interested.

HostgatorMemberHere are a couple of thoughts. First, it is quite possible that you have an air bubble in the line that has to be bled. That would make your clutch react in the manner you describe. Check the bleeder valve to see if you can get all of the air out of the line.

Another thought is a binding, slipping or broken connector rod with the master cylinder. There is a connector rod that comes up to the base of the cylinder that can either have been knocked off altogether or which may have loosened up and has worked its way loose. If this is the case, check the connector shaft closely to see where it has loosened; reattach it and retighten it.

If this isn’t the problem, check to see if the Y-connector hasn’t begun binding, knocking the connecting rod off. If this is the case, you will have to replace what appears to be a fork unit and rods, adjusting them to the specs you find in the service guide.

HostgatorMemberHere are a couple of thoughts. First, it is quite possible that you have an air bubble in the line that has to be bled. That would make your clutch react in the manner you describe. Check the bleeder valve to see if you can get all of the air out of the line.

Another thought is a binding, slipping or broken connector rod with the master cylinder. There is a connector rod that comes up to the base of the cylinder that can either have been knocked off altogether or which may have loosened up and has worked its way loose. If this is the case, check the connector shaft closely to see where it has loosened; reattach it and retighten it.

If this isn’t the problem, check to see if the Y-connector hasn’t begun binding, knocking the connecting rod off. If this is the case, you will have to replace what appears to be a fork unit and rods, adjusting them to the specs you find in the service guide.

HostgatorMemberLet’s start with a basic question, did you check the transmission fluid level? If it is low, one of the symptoms is just what you describe. To find out, run the Toyo for about 20 minutes, park it with the handbrake set. Then, with your foot on the brake, the only way the transmission will work correctly, push the transmission through each gear setting for a moment of two to get things lubricated correctly. Finally, pull out the tranny dipstick, wipe it and reinsert; then take a reading. It should normally be between the low and full marks. If it is below the low mark, you have found the reason for the poor shifting.

To fix it, get a couple of quarts of the proper transmission fluid (if the manual reads Dexron or another similar brand, don’t try a substitute, use what is required) and a funnel. Then, pour, a bit at a time, the fluid back into the transmission, checking often to make sure you are not overfilling the transmission, which is just as bad as underfilling.

Another potential problem that can be shown by draining the transmission and dropping the pan to get out any remaining fluid is a plugged filter and screen. If the filter is plugged up to the point where the fluid flow is cut way down, then it is possible that your transmission will act in the manner you describe.

If you find this is the case, replace the transmission filter and screen and replace the transmission cover, using the proper sealer before you insert the screws. Then refill the transmission with a fresh load of fluid and you should be good to go.

One other suggestion, but this is getting into the area where you will need a tech to tear down your transmission, unless you have the facilities to drop the transaxle, is the valve body. If one or more check valves is either lazy or stuck, then your Toyo will perform as you describe. Let me know if this is the case and I can direct you from there.

HostgatorMemberLet me ask, first, you are talking about an automatic transmission, right? Sometimes, folks will forget to let me know which type of tranny they are trying to shift. There’s a big difference in what may be causing the problem, as you can be sure.

Here are some thoughts about both potentials, automatic and manual.

Automatic:

If you have been trying to hand-shift an automatic and you have badly missed a shift point, then it is possible that you have badly smoked the clutches and bands. Yes, they are usually immersed in transmission fluid, but, if your tranny was down a bit to begin with and that is what started your problems with shifting, then, it may be that the clutches/bands were high and dry when you shifted and when the revs shot up, they smoked badly.

The same is true of the torque converter. If your transmission was down on transmission fluid in the first place, then, it was likely trying to send a flow of transmission fluid to the impeller blades, but for one problem, there was no fluid to send. The high-and-dry converter, at this time, could easily smoke. Or, it could also cause the gearing to smoke.

Finally, if your automatic’s filter/screen were plugged up and the entire transmission from impeller to valve body to output shaft were fluid starved, then, it could easily set up an overrev condition — for a while, until things blew out totally — as you described and it could easily produce all kinds of odorous and dense smoke. In any of these instances, you are looking at a rebuilt transmission that will cost you about $3,400 or so, unless there are parts you can save or unless you can find a suitable transmission at a salvage yard that you trust which can save $1,200 to $1,800 easily.

Manual:

In a manual transmission, there is a condition that can cause lots of smoke, a sticking throwout bearing.

The throwout bearing is the device that separates the clutch plate/face from the the engine side of things, or, it is supposed to. If the bearing fails and the clutch and friction plate remain locked, even though you are pressing the clutch to the floor, then it is more than likely you are seeing the clutch plate itself burn out, emitting great clouds of smoke.

If this is the case, then you are looking at replacing the clutch plate and facing, as well as the friction plate and facing on the engine side of things, as well as the throwout bearing and, possibly the cable because it may be binding in its runner, helping to cause the problem.

You care likely looking at a problem that will cost you the better part of $2,250 for all the parts and labor.

I’d suggest your next move is to the back of a ramp truck and then to a reputable transmission shop where the problem can be diagnosed.

Two things, please let me know which type of transmission you have and second, let me know what the tech finds.

HostgatorMemberSince my various gurus haven’t responded to this question the way I would like, I’ll give it a go.

With the way today’s shifting mechanisms work, you will have to find a way to make the “shift-by-wire” mechanism work with a mechanical one. I suppose it is possible, but, given the fact that most electronically based shifters are actually just double-pole-single-throw switches, you might find yourself working incredibly hard to make things work.

Honestly, I have never tried to interface an “shift-by-wire” system with an old, what you might call, analog-based system, but I do know that if I were to try to make an electronic shift system work it would require a lot of effort to make it happen.

My thought would be this: drop back a few years, say to an old F-150 of the 1995 timeframe. You can likely find one in a local salvage yard and pull the transmission and shift mechanism. Since the 1995-era F-150 still relied on mechanical linkages and the like, you should be able to make it work with your restoration project.

I do hope this helps.

HostgatorMemberAug. 30 update: I am still trying to track down the exact information you need. The issue is this today’s transmissions are computer- and electronically-electronically controlled. Due to this fact, there are some bad mismatches that occur when you go from today’s digital system to the analog world of the 1960s. That said, though, don’t give up hope, I’ll find the answer for you. It is taking far longer than I want, though.

HostgatorMemberThis is an interesting question and, believe it or not, has me stumped right now. Give me a day or so to get the answer together and I will put it right here.

Aug. 27 update: I have been looking for the information, but some of my gurus won’t be available for a couple of days, so everything is delayed. I will put it up as soon as I have the information.

HostgatorMemberNo need to replace the STX yet, just have the tranny shop recheck the OBD-II outputs and the chances are good that they will find they missed the fact that there’s another solenoid that’s actually sending the code. Have your shop look at the Pressure Control “A” Solenoid.

One of the functions of the this solenoid is normalize the output from the oil pump so that engine response remains smooth. The Transmission Control Module (TCM) sends out codes that ask the oil pump to change the output of the pump in response to changing driving conditions. For example, if you are driving uphill, the TCM will ask the oil pump to increase the flow in response the need for more engine/transmission (drivetrain) response as your pickup heads up hill, and so on.

The P0600748 combination is pointing at Control “A” Solenoid. It mauy be due to a faulty solenoid — it would be a good idea to have it replaced, just to be sure — or it could mean there’s a short or open in the wire loom or it may just be a poor connection.

Have your tech concentrate there and your likely to find the problem and keep your STX on the road as long as you want it.

August 25, 2016 at 12:44 pm in reply to: My 2001 Nissan frontier wont shift out of second gear the od light keeps coming #6693HostgatorMemberHere’s my thought: go back to your technician and have him run the wire pair for the throttle positioning sensor (TPS). It may take some time as the tech will have to go to the TPS connector base and run each section of the circuit to find where the ground is occurring.

No, there’s no easy fix for this. It just takes scut work and time. However, if you want your transmission functioning normally again, the only way to do this fix correctly is patiently and step by step. It may also be costly because it could take the tech several hours to do this work. I can’t begin to estimate the number of hours needed because I don’t know where the break and ground might be.

You might get lucky and the break could be right at the terminal points for the TPS. If that’s the case, the tech may be able to cut out and replace only one section of wire, though, knowing what I know of electronics, the best bet is replacing the wire end-to-end, just to be on the safe side. If your tech is good, though, and he recommends only replacing a piece of the wire, then I would go ahead with confidence.

Getting back to costs for a minute, by the way, I use a base figure of $150 per hour time (it’s an average of hourly rates at shops across the country). If the fix were to take four hours, it will cost you about $600; 12 hours will cost about $1,800, more or less. I am listing the figures here to let you know what you stand to spend, if your tech can give you an estimate of time.

Let me know what the results are, I am interested.

HostgatorMemberThe long answer — and the short answer is — uggh! Without the fluid, the transmission will put its gears up and head for the scrapheap. I have to tell you that up front. I am honestly surprised that you even have reverse at this point because the chances are good that if you were to pull the tranny apart you would likely find that the planetary gears have fused due to the heat and the lack of lubrication. You will also find that the bands and clutches have become a somewhat formless mass of metallic goo. And, we won’t talk about what may have happened to the valve body; input shaft, and output shaft. Suffice to say, the outlook for your transmission is not good.

There are several steps you can take to try to remedy the problem. The first is to get your Monte to a trained technician on a ramp truck. The second step happens once it’s there, of course, the tech will crack the case and take a look inside. As the tech drills down through the various pieces of the transmission, there may be pieces that can be saved and recycled. Indeed, it is possible that there may be enough left in good shape the at you can get away with replacing only the seriously damaged parts. Which parts might those be? I can’t honestly say at this point which parts might be in good shape, that’s up to your technician to find. The third step is easy, the technician gives you a report on what is good and those parts that have been damaged beyond repair. The fourth step is for you to make a decision on what you might do.

You may find that you will be able to replace parts and keep the cost below $2,000, which is the plateau I use to say whether it’s worth replacing parts or replacing the transmission with a rebuilt. I know that figure sounds high, but when you think of just how quickly the costs rise in transmission work you will see why I set a rather arbitrary figure. As to what goes into the figure, it varies from job to job as you can’t say whether replacing the torque converter and a set of clutches will make up the cost or whether replacing the planetary gears and clutches/bands will make up the cost. Or, whether replacing the TCU, sensors and solenoid packs will make up the cost.

Here’s is my take on your whole issue: replace the tranny with a rebuilt. I know the cost will be about $3,200 or so, but it will be worth it. Here’s what usually — not always — happens if you try to do the piece-by-piece replacement. Any parts that are still in the “good” category and are reused will have probably been weakened by their sojourn in the transmission without fluid. They may appear good but the high heat in the transmission will likely have cost them their flexibility, making them rigid and prone to failure. It won’t take long until the parts you think are good to show their true colors by failing. That failure could even have bigger consequences as the shards will spread throughout the transmission causing even further damage to the point that the transmission will be a total loss.

By the time you have finished paying for damages that may have been caused by failing parts, you will quite likely have passed the $3,200 cost for the replacement rebuilt that should have been installed in the first place.

So, please take this recommendation: replace the transmission with a rebuilt. It may seem like a high cost to pay, but the price that you will pay after you eventually replace the tranny anyway, will be far more than cost for a rebuilt now. Let me know what you think and what your plans are.

HostgatorMemberThe long answer — and the short answer is — uggh! Without the fluid, the transmission will put its gears up and head for the scrapheap. I have to tell you that up front. I am honestly surprised that you even have reverse at this point because the chances are good that if you were to pull the tranny apart you would likely find that the planetary gears have fused due to the heat and the lack of lubrication. You will also find that the bands and clutches have become a somewhat formless mass of metallic goo. And, we won’t talk about what may have happened to the valve body; input shaft, and output shaft. Suffice to say, the outlook for your transmission is not good.

There are several steps you can take to try to remedy the problem. The first is to get your Monte to a trained technician on a ramp truck. The second step happens once it’s there, of course, the tech will crack the case and take a look inside. As the tech drills down through the various pieces of the transmission, there may be pieces that can be saved and recycled. Indeed, it is possible that there may be enough left in good shape the at you can get away with replacing only the seriously damaged parts. Which parts might those be? I can’t honestly say at this point which parts might be in good shape, that’s up to your technician to find. The third step is easy, the technician gives you a report on what is good and those parts that have been damaged beyond repair. The fourth step is for you to make a decision on what you might do.

You may find that you will be able to replace parts and keep the cost below $2,000, which is the plateau I use to say whether it’s worth replacing parts or replacing the transmission with a rebuilt. I know that figure sounds high, but when you think of just how quickly the costs rise in transmission work you will see why I set a rather arbitrary figure. As to what goes into the figure, it varies from job to job as you can’t say whether replacing the torque converter and a set of clutches will make up the cost or whether replacing the planetary gears and clutches/bands will make up the cost. Or, whether replacing the TCU, sensors and solenoid packs will make up the cost.

Here’s is my take on your whole issue: replace the tranny with a rebuilt. I know the cost will be about $3,200 or so, but it will be worth it. Here’s what usually — not always — happens if you try to do the piece-by-piece replacement. Any parts that are still in the “good” category and are reused will have probably been weakened by their sojourn in the transmission without fluid. They may appear good but the high heat in the transmission will likely have cost them their flexibility, making them rigid and prone to failure. It won’t take long until the parts you think are good to show their true colors by failing. That failure could even have bigger consequences as the shards will spread throughout the transmission causing even further damage to the point that the transmission will be a total loss.

By the time you have finished paying for damages that may have been caused by failing parts, you will quite likely have passed the $3,200 cost for the replacement rebuilt that should have been installed in the first place.

So, please take this recommendation: replace the transmission with a rebuilt. It may seem like a high cost to pay, but the price that you will pay after you eventually replace the tranny anyway, will be far more than cost for a rebuilt now. Let me know what you think and what your plans are.

HostgatorMemberIt’s little wonder that you are having problems finding someone who will look at the problem. The scene you have described is a technician’s nightmare, an electrical intermittent. With an intermittent, the technician knows only two things: 1. there’s a problem with the TCU (I would check the ECU, as well, just to be sure); 2. the problem is intermittent.

At this point, I will guarantee that anyone but a tech who is an absolute fanatic on finding things will throw up their hands and walk away, muttering to themselves. The fanatic will dive in and try to find the intermittent problem, but the chances are good that eventually even the fanatic will give up and move on.

The short answer is that if there is an intermittent with the TCU, perhaps it is time to think of putting your LHS out to pasture in favor of something a bit newer. If you get get under your LHS safely by sliding and looking around with a flashlight, you will see the enormity of the problem facing you.

See the rather large transaxle between the front wheels and under the engine. Somewhere in the housing a wire — a single wire — is grounding out and causing the problem. The trouble is which one and where. Normal diagnostic troubleshooting has a technician putting a signal (electric voltage) through each wire in a particular system and then taking a volt-ohhmeter and checking the wire from point to point as described by the service schematic.

To find a problem with the TCU signal, believe it or not, you have to go back to the console in the passenger compartment, pull the housing and then finding the pair of wires (you need a signal wire and ground to complete any circuit) that control the TCU. Look at the loom of wires that is underneath the console. Though I haven’t counted the number of wires in a particular transmission control loom, I believe you may have 20 or more wire pairs to run. Each circuit has to be painstakingly checked and when the signal ducks into the bellhousing (the tranny cover), where does it go? You will have to pull apart the entire transmission assembly to find the TCU signal. That is a very expensive and frustrating proposition at the best and absolutely maddening at the worst. It is enough to send veteran technicians running out babbling to themselves.

That’s actually the reason no one wants to take on this task. It is not one that can’t be done, it is just that it is so monumental in scope (passenger console; wire loom: trace out through the firewall; trace from the firewall to transmission; transmission housing) that no one will take it on. There is no percentage and the cost to you will be quite a bit.

Let’s say you do convince someone to take it on. It will likely take at least two full days or more to find each leg of the circuit and trace it. You can add on another two days if you have to strip down the transmission housing and tranny parts to find the intermittent.

You do the math and see if it is affordable. Let’s base it on the maximum number of days to do the work, four. At the moment, the average technician’s hourly is over $150 in many places. Let’s use $150 per hour as the base, though. One day is $1,200 in labor and four days is just under $5,000. I am not kidding about the time it takes; an intermittent, as noted, is a technician’s nightmare.

The question you have to ask right now is this: “Am I willing to pay more than the cost of another rebuilt transmission to find the problem?” I think I know the answer to this but I think you should ask the question and think about the answer you get.

At this point, I think your next move should be to a dealership or Craigslist or another venue to find another vehicle. In the long run, you will honestly save money.

HostgatorMemberFrom what you have told me, it seems like you have a problem in one of the solenoids that controls the gear choice. You see most four- or five-speed transmissions use two solenoids and electronics to determine the proper gear. A solenoid can certainly emit smoke when it fails explosively under stress and that could easily have been the cause of the pop and smoke.

To my thinking, then, your transmission is likely overall in decent shape, however, there’s a problem throwing it into limp-home mode. The problem is in the solenoid pack in the valve body.

My advice is to take your SUV into a shop where they can open things up and look inside. Unfortunately, you do have to crack the case to get to at least one of the solenoids. There is one inside the valve body and one external on the valve body itself. More than likely, you are looking at replacing one or both of the solenoids to restore your transmission. You are looking at a cost of about $500 to replace the pair.

One other suggestion is this have the technician do a complete diagnostic with an OBD-II scanner. It should turn up any other problems that may be lurking in the tranny.

HostgatorMemberI don’t know how to tell you this gently, but your automatic transmission has gone on to its earthly rewards. The seemingly innocent shift from drive to reverse put so much stress on the transmission that one or more major systems have given up and stopped working. At a guess, I think the torque converter is gone, as are the clutches and bands and, as a topper, I think the planetary gearing aren’t in their orbits anymore. I don’t want to think what may have happened to the other parts of the transmission.

Suffice it to say, your Nissan won’t be going anywhere for a while, unless it is on a ramp truck to a service shop. Your only course of action is replacing the transmission with a rebuilt, for starters. That will cost you about $3,400.

Also, you are going to have to have the technician pay close attention to the input and output shafts. It is possible that the reverse torque that happened may have thrown them “out of true.” In other words, instead of working correctly, they are kind of wobbly and that means all kinds of nasties can happen. A wobbling shaft can set up a set of vibrations that cannot only damage linked components but, worst case, can destroy them. The good news is that you did quickly get back into the proper gear. The bad news is that it happened in the first place.

HostgatorMemberI don’t know how to tell you this gently, but your automatic transmission has gone on to its earthly rewards. The seemingly innocent shift from drive to reverse put so much stress on the transmission that one or more major systems have given up and stopped working. At a guess, I think the torque converter is gone, as are the clutches and bands and, as a topper, I think the planetary gearing aren’t in their orbits anymore. I don’t want to think what may have happened to the other parts of the transmission.

Suffice it to say, your Nissan won’t be going anywhere for a while, unless it is on a ramp truck to a service shop. Your only course of action is replacing the transmission with a rebuilt, for starters. That will cost you about $3,400.

Also, you are going to have to have the technician pay close attention to the input and output shafts. It is possible that the reverse torque that happened may have thrown them “out of true.” In other words, instead of working correctly, they are kind of wobbly and that means all kinds of nasties can happen. A wobbling shaft can set up a set of vibrations that cannot only damage linked components but, worst case, can destroy them. The good news is that you did quickly get back into the proper gear. The bad news is that it happened in the first place.

August 17, 2016 at 1:57 am in reply to: Can't put my car into second gear unless I'm below 5mph #6675HostgatorMemberGo back to your mechanic and tell him to readjust the gearshift cable and then tell him to look at second gear itself and see if the high-speed synchronizer is working correctly for second gear. And, for good measure, have him check to see if there might be bent shift rails.

It is true that after major transmission work things do have to work in so that everything will seat correctly, but, you should be speeding up after your shift from first to second and not slowing down. The fact that you have to slow down indicates that there is something going on that the mechanic may not have found when he did the work and now is trying to fudge a way out.

With that said, this is something he can’t just fudge his way out of. Your transmission isn’t working correctly, even though you had it rebuilt. It should be working correctly through each gear and not acting up. It’s quite obvious that something was missed somewhere so it is up to the mechanic to put it right — and to service it under a warranty so you don’t have to pay twice.

Just having your transmission rebuilt is expensive and time-consuming enough. You shouldn’t have to spend the time or the money to have it done all over again for something that the mechanic, like as not missed.

Or, to ask the question, when the transmission was serviced was something bent that should not and would not have been bent if the work had been done carefully in the first place. This not withstanding, your transmission should be working correctly now and the mechanic has a responsibility to make it right.

Please let me know what you find out.

HostgatorMemberThe first thing I would recommend is that you take your Volvo over to either your dealer or a good independent transmission shop and have them run a complete diagnostic with an OBD-II scanner. The scan will show the general areas where there are problem and, if you are lucky, one of the scan codes that is stored in memory will show the exact problem.

You may wonder why the diagnostic results don’t provide you with the exact information you need, which is a good question. The answer is simply that the scanner isn’t designed to work with the transmission control module specifically. It is designed to work with the engine control module which is the master computer for the engine. Essentially, it is a master library that not only stores trouble codes that may be generated, but it also holds the software libraries that your engine needs to function correctly. The transmission’s control software is stored in and handled by the transmission control module. The module also generates error codes that are stored in the engine control module’s memory.

Because there are so many potential variables and possible problems involved it is nearly impossible to generate an exact error code to match a problem. The codes give you a range of problems that may be occurring. The point here is that the codes also will tell you generally where the problem is originating.

With that said, it is quite possible that your transmission is hanging somewhere so that computer messages aren’t getting through. In this condition, your tranny can easily go into limp-home. That’s why you need the diagnostic scan and error codes. There are so many possibilities that the scan will point you in the direction you need to go.

In your case, I would also suggest having the engine control module checked along with the transmission control module as they may be either failing or in the process of failing and generating the limp-home code. And, while you are at it, have the technician check all of the sensors that may be interacting with the control modules. In 2005, your Volvo was manufactured by Ford and so the tranny would likely have interacted with about a dozen or so sensors (the Mass Air Flow, the Manifold Air Pressure or the Throttle Positioner Sensor, for example) so it also makes sense to have them checked out.

Next, have the solenoid packs in the valve body checked. There may be as many as three solenoids in your transimission. They control the selection of the proper gearing for a given range of speed and engine rpm. If one or more of the solenoids has failed your transmission will automatically go into limp-home mode.

If nothing turns up in those checks, it’s time to start thinking about replacing the transmission as the piecemeal cost of repairs that might be needed will rapidly build up and past the cost of a rebuilt transmission.

Let me know what you find, I am interested in finding out.

HostgatorMemberActually, I think this has happened. There’s a rather large bushing that is surrounds a pin that is enclosed by the working end of gearshift cable and somehow the bushing has either worked its way loose and fallen out, leaving the gearshift to flop around the pin. So, instead of allowing your tranny to move from gear to gear, the connector at the end of the cable is only able to stay seated long enough to enable the transmission to go into second. First, third, fourth or fifth are no good.

You will need to obtain a transmission shift cable repair kit. It consists of a couple of bushing halves, the proper retaining and lock clips. At this point, I would suggest that if you know a do-it-yourselfer who is comfortable or has knowledge of shift cable repairs, contact that person and ask for assistance.

You can also find any number of helpful videos on the YouTube that will show you what to do. Again, though, if you aren’t comfortable with or used to working around the confined areas under the hood or under the engine (if you can’t access the cable from under the hood, you will either have to raise the car up to working height on a lift or put it up on a hydraulic floor jack for clearance or you will have to get underneath the vehicle and work there), it’s a good idea to let someone who either has the facilities and expertise do the work.

I am not saying that you can’t do it, it is just that I am suggesting that if you need this done quickly, then you should let someone else handle it. However, with that said, there are kits available that will fix this problem.

-

AuthorPosts

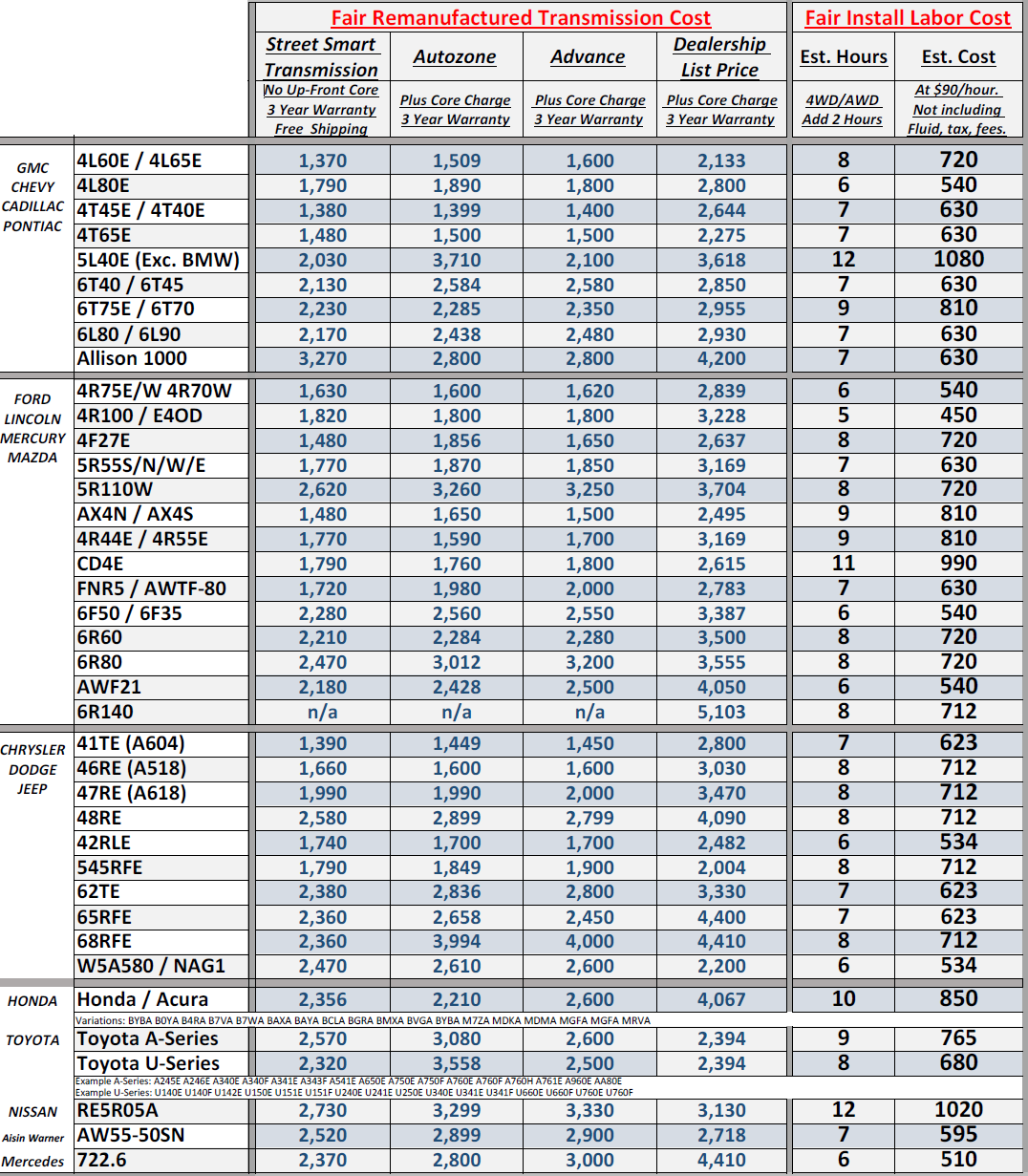

Fair Replacement Transmission Cost by Vehicle

- Use the Year / Make / Model lookup tool to determine what transmission your vehicle has. [transtar]

- Find your transmission model in the table below for fair prices from reputable suppliers. Also fair labor cost for local installation at a local auto repair shop.

- Get a free estimate on a remanufactured transmission by email.

Fair Remanufactured Transmission Price Ranges by Transmission Model Updated May 1, 2018