Forum Replies Created

-

AuthorPosts

-

HostgatorMember

Get your Merc out of there yesterday! I am not kidding! There is no reason on this green planet that they should ask you for your driver’s license and registration. About the only reason I might suspect is this: they are going to try and open you a line of credit so they can do the work and get paid for it. You, of course, would be left with the bill. Now, I don’t know if this is the case, it is just my sense of caution jumping up and down, but, when asked for something out of the ordinary, I am not easy with it.

As the the price, the general cost of a new transmission in your part of the country — I do know of the area — should be about $4,400, but, that’s for a more standard car like a Toyota Camry or a Honda Civic. Mercedes-Benz vehicles are notoriously expensive to service so the $6,200 isn’t all that outrageous, however, I think it is too high, myself. A car is a car is a car and a transmission is a transmission is a transmission — and here’s the but — a Mercedes is expensive to repair. However, in 05 they had more standard transmissions without some of today’s improvements like dual-clutch or dual-clutch and eight-speed, so your 350 should come in, I would think, about $5,200. I know it’s not much comfort, but, if you have to replace a transmission that’s what it is.

Again, here’s my advice:

1. Get the Merc out of there

2. Find another independent shop who specializes in Mercedes-Benz cars

3. Have a thorough diagnostic performed with the most up to date software

4. Get a print out of all of the issues identified

5. Sit down and talk with the technician and discuss the diagnostic reportI think you may find, as I suggested, that the problem is in the electronics. It could also be in the mechanical stuff, but, I don’t think so.

Let me know what you think of the plan. You will have to factor in the cost of the trip to the new shop on a ramp truck or on a tow hook (I prefer the ramp myself). One last thing, they might try to tell you that you can’t take your car out; that you owe them the work, and such stuff. If they haven’t done anything except give you a date for completion it seems to mean that they haven’t done any work?

You never did tell me if they had done work, did they? If so, then you could be on the hook for everything because of various things including a goodie called a mechanic’s lien where the mechanic can keep your Merc in payment of the bill, if you don’t pay it. Please let me know if they did any work and what promises were made by both sides. I’d be happy to help you work this out — via email as I am not on the West Coast and it’s the best way.

Need a replacement transmission? Quality transmissions are hard to find. Free estimate to your email.HostgatorMemberHere’s my suggestion: Start from the top! First, take your Mercedes to a good, independent service shop with trained technicians. I honestly would suggest going to a dealer who has NIASE-certified techs and who have access to the latest Mercedes-specific diagnostic software.

Second, I would have them run a complete diagnostic on the unit. I know you have had diagnostics run as you seek specific answers, however, I don’t know if you have taken a systems analysis approach. In other words, look at the whole powertrain as a complete system and then begin your hunt from there. In this way, you can take steps that might otherwise be missed. For example, let’s say you the manual or test manual calls for a test of the engine’s Engine Control Module (ECM) or the master computer for the whole vehicle. This is the system that can listen for up to a dozen reports from subsidiary systems that impact the operation of your vehicle.

As you know, there is a specific transmission control module (TCM) which is responsible for the operation and reporting of the transmission and its subsystems. The interesting thing about this is that if you were to look at a schematic diagram of the reporting systems in relation to the transmission you will likely find that the brakes may be (and do) report to the TCM. Likewise, the emissions system — or parts of it — report to the TCM. The Mass Air Flow sensor and Mass Air Pressure sensor, as well as various wheel-related sensors all report to the TCM in order for it to choose the right gear when certain conditions are met. The Throttle Positioning Sensor and Coolant Temperature Sensor also report to the TCM (the transmission has its own piece of the cooling system in most vehicles).

As you can see the TCM reaches out and touches a number of related systems that actually either report directly to the ECM or to the ECM and other subsystems which is why I think you need the systems analysis approach to the problem.

Quite frankly, I think that if you were to replace the ECM or the ECM and its related boards, I think you would see most, if not all, of the problems that your transmission is experiencing clear up. I say this because, as I see it, there is something compromising the signal flow to the ECM. It could be the ECM itself or one of its related parts.

Since it is likely that this automotive powerhouse is throwing problem, it is more than likely having not only an impact not only on the transmission but also the engine componentry as well. It doesn’t hurt to replace the ECM and it is a relatively inexpensive fix for your transmission problems. If the problems continue, swapping out the TCM is your next move.

Remember, though, all of this should be done after your technician has run down all of the leads that may have been generated by the system-wide diagnostic.

HostgatorMemberWhen you are shifting through the gears, one of the things that happens is that a gear, called a dog, moves along the shift rails until it meets the “dog collar” on the gear. Until this happens, the transmission won’t go into gear, no matter how hard you try.

Now, what could keep this from happening? There could be cable binding that is preventing the dog gear from moving along the rails or it could be dog gearing itself. It may simply be gone and if that is the case, then you are looking at the rebuild of probably two gears. Each rebuild is probably about $400, so it will cost you $800 or so.

If you are luck, though, and there’s a cable bind somewhere that is preventing the dog gearing from sliding along, then you are looking at a fix that is just as complicated, but it only involves a cable and a cable runner. This one should average about $500.

Let’s say, though, that the synchros on the T100’s first two gears are shot, then, you are looking at devices that potentially can keep your shift from working at all, as it is now doing. Replacing the synchros is more expensive, probably $1,200, but it is worth it if you are planning on keeping the Toyo.

If the synchros are shot, though, the chances are also good that the gearing itself may be gone so that it may be a good idea to think about replacing the transmission altogether. A rebuilt is about $2,400 or so with labor.

One last suggestion is this: the T100 is 23 years old now and it is exhibiting signs of major transmission issues. Since it is, ask yourself this question: do you want to make the investment in the T100, a vehicle that is on the edge of no longer having a ready supply of replacement parts available (most carmakers keep about a 20-year supply of parts available). And, the parts that are available are going to go up.

Now, unless you plan on restoring and making it an antique in a couple of years — a great investment in tough times — then I’d suggest selling out and moving on. A newer truck is more reliable and will save you in the long run.

If you are planning to go the antique rout — quite understandable — and the T100 has special meaning to you, then, I would opt for the replacement tranny. It will save you work.

HostgatorMemberLet’s see what’s going on here! The transmission fluid has never been changed, right? You don’t say how many miles are on the F-150, however, since it’s an 07 and if it has been driven an average of 12,000 miles per year or so, it likely has about 100,000 miles on it.

There’s a problem staring at you, right away. Transmission fluid should be replaced at between 30,000 and 50,000 miles (I know there are some supposed 100,000-mile fluid settings but I don’t think it should ever wait that long). And, assuming there’s 100,000 miles on the F-150, you should have changed out the transmission fluid at least twice. It’s just not meant to be sitting in the transmission that long.

If it has been there and if it is black, obviously, it has to come out. The best way is to simply drain the transmission and then remove the pan cover to get the last quart out. Never use a flush, especially a pressure flush, to clean the fluid. Though some shops use and advocate a power flush, in my hunble opinion, it just leads to transmission damage. The reason I say this is simple: when you attach the high-pressure line to one side of the transmission and apply air pressure, all you are doing is blowing everything out of the transmission.

It does clean everything out, including hardened deposits which will break off and rip through other parts of the transmission, causing damage. At the very least, it is possible with a high-pressure flush to see not only torque converter damage but also impeller damage as well as trouble with the gears and bands/clutches. It is even possible to have check-valve damage in the valve body as the small valves plug up with pressure-driven gunk.

That’s why I recommend the more labor-intensive draining, it is better for the transmission, all around.

Next, swap out the transmission filter so you can be sure you are starting off as cleanly as possible when you add in the new transmission fluid. Now, add in the right amount of transmission fluid — check the owner’s manual. Things should work better when you have completed this.

I am not saying you won’t have further problems. After all, you said nothing has been done to the transmission fluid and it is dark, which indicates that there is very little capability left to it. I am saying that changing the transmission fluid is the normal first step to see if there might be more damage (I suspect there is).

If you are very lucky — and my hunch is wrong — you won’t have further problems with the F-150 once you’ve swapped out the fluid and everything will work correctly. However, you have to remember that the new transmission fluid is also detergent in nature and any buildups will break loose and they may also cause damage. The reason broken off materials can cause damage is that they are usually rock-hard and can easily either lodge in sensitive parts like the check valves or they can actually harm things like turbine blades, further upsetting things.

I think you are right in keeping the other unit — I am assuming the other unit you are referring to is a transmission — because the potential for problems in the first, honestly abused tranny are likely too great to fix. I am only advocating the new fluid in the first transmission to see if there is any possibility it can be used. If it can, then you are ahead of the game, if not, you have a backup to swap in quickly at a cost of about $1,200 in labor or so.

One last question, what was the transmission error code?

HostgatorMemberNow we are getting somewhere! The broken traveler cover could indicate — likely it does — that the shift cable is either binding (not likely) or stretched so far that it isn’t even working. So, what is happening is that you are hearing clicks as the shifter goes through the gates, where everything stops.

If you have access to the right tools and feel comfortable doing this, I would suggest that you park your car on a flat or level surface and set the parking brake. Once you have the brake set, I’d get inside the gearshift console and access the gearshift adjuster cable. It should be at the end of the cable with the sheat. At the same place, you will find a nut with a steel wire running through it. This is the gearshift cable and adjustment net.

Loosen the adjustment nut a bit — only until you can move the steel cable easily. Then, using a Vice Grip (R) style pliers, first pull the cable until it tightens somewhat in the carrier (sheath). Don’t pull it very tight or you risk damaging things. Once it is tighter, tighten up the nut and try shifting your vehicle (don’t forget to press the clutch). I think you will find things starting to work a bit better, although the fact that the outer sheath is also broken does alarm me. It may indicate that the entire gearshift cable/adjuster assembly is broken and has to be replaced. This could easily account for the way your tranny is acting. Though it is not a hugely expensive repair — $350 or so with labor — it is important that everything is set up as it is supposed to be or else your transmission won’t work, no matter what you do.

After it is fixed — I’d let a technician do this as it involves attaching the carrier and then threading the cable correctly to each gear — try starting up, with the parking brake set so the vehicle won’t move. I’ll bet that your Vibe will now stall — which is what it should be doing.

HostgatorMemberYou can put in the rear end because what I think happened is that you’be blown out the banjo box (also known as the universal hub). The reason I say this is simple: You said when you turned left, the Astro just revved and made a grinding sound. This tells me the transmission is okay because it is trying to get power to the rear wheels. The rear wheels aren’t getting the power because the universal joint is fried.

Another telltale here is the way you describe the roll onto the flatbed. If it is jerking regularly, it indicates something is trying to take up gearing, but is slipping.

If it were the transmission, you would find that there would be no grinding sounds at all. Instead, the engine would turn over and run and there would be silence from the transmission. There would be no sounds coming out of the rear end. You might hear the gears trying to engage, but that would be about all you would hear and that would be a whooshing sound, for the most part.

I think you will find that when you swap in the new rear end that things will work pretty well. Just take your time and don’t leave the parking brake on.

HostgatorMemberI have a question for you:

When you let the clutch come up, does it feel as if there’s contact?

Here’s a suggestion to let both of us know where to look — with the parking brake set, let the clutch pop up. What happens? Let me know, if you would and we’ll look at a couple of things.

HostgatorMemberI can see why you are getting the solenoid error. I would have to agree that, at least, the solenoid pack for your second/reverse is shot. But — and there are several buts here — there’s a lot more going on, going back to the point where the dealer did the flush.

Of course, you should have the transmission fluid drained and replaced according to the schedule in the owner’s manual. The factory knows how long the fluid will last in the crankcase and, of course, it has to be replaced then.

With that said — and here’s the first but — your dealer had the transmission flushed. Usually, the shop will put a high-pressure hose on one side and blow in a lot of air to clean things out. In a perfect world, that would be the best way to go, but, the high-pressure blast not only strips everything out of the transmission but it can actually damage some of the more delicate components. You probably want to know how this happens and it is simple, the blast picks up all of the good stuff and the bad stuff, like any deposits that may have built up (they can be about as solid as cement) and will blast them through the interior, damaging everything in their path, like turbine blades, clutch packs and anything else. You just can’t tell the depth of the damage. Had the dealer just drained the transmission and then removed the transmission cover plate on the bottom, you would have been a lot better off as everything would have drained away. It is slower but it is safer.

Your dealer said there was an internal problem that caused metal filings to build up. That may be true, but, what caused the shavings to form in the first place? The chances, in my opinion, are very good that when the flush occurred shards of deposit slammed into small parts and damaged the parts, ripping off small pieces of metal which then fell to the bottom of the crankcase and which were then captured by the slightly magnetic transmission pan bolt (it usually captures a lot). Again, the flush started the problem, in my opinion, that is now showing up. In fact, I think it also caused the solenoid failure because of stuff that was dislodged and which may then have relodged around the solenoid itself (there are two, one internal and the other on the valve body casing — I’m talking about the interior one).

Of course, it may not have caused the solenoid failure in this instance. It still could have been part of the failure because a sensor may have been damaged and that damage may have put faulty signals through to the solenoid, causing it to fail. (It’s another but.)

Then, of course, the flush may have stirred up enough gunk from the bottom of the pan to cause one or more of the check valves in the valve body to stick. If that’s the case, you will not only lose the specific gearing to which the transmission fluid was being directed through the valve body, but (another one of those things) it also may have caused further damage as there may have been too much transmission fluid being pushed though one or two gears, while other gears may have been starved for fluid, causing more damage.

I think, by now, you get the drift of my idea. The flush that the dealer pushed through your Equinox’s transmission was like dropping dynamite into a closed space and covering it up tightly. The only result of something like that is basically taking what might have been a relatively easy event and turning it into something a lot more severe.

Overall, though I honestly don’t like saying this, I believe your transmission has failed. I wish it was just limited to the solenoids as they are a relatively inexpensive fix. That said, the flush likely caused a chain of failure within the transmission that has resulted in your Equinox’s need for a rebuilt transmission. It will cost about $3,400.

Here’s a thought: why not show this answer to your dealer and then ask what he will do to help you out with the repair. If he offers to cut the bill by 10 percent, you know you are on to something, however, be aware that dealerships routinely will “give you a break” of about 10 percent to make it appear they are helping out a lot — they’re not really. The reason I think it’s a positive is this: it opens up the whole topic of the dealer contributing a lot more to the replacement of the transmission which was likely messed up by the flush. Flushes are never a good idea, unless the transmission is new or extra clean because there is just too much chance for error.

I would keep pushing the replacement idea with the dealer. If you would like he can contact me through the http://www.transmissionrepaircostguide.com and I’ll be happy to help with this. I am happy to help.

As to who you should listen to, I think you can see which way my thinking lies. Your mechanic is a great source of information about your van. I’d listen to him (or her) first.

HostgatorMemberI have some interesting news for you but first you have to do something for me. Is it a deal? Your part of the deal is simple, take your Altima into a Nissan dealer and have them do a complete diagnostic on the transmission with an OBD-II scanner. That’s it and it plays into the my part of the deal. It is to tell you that I don’t think you have to replace the entire transmission.

The transmission of the 2008 Altima, like most fairly late-model vehicles, is primarily electronic with mechanical parts. The mechanical parts are those you need to go from gear to gear and keep rolling. The electronics control everything else.

From the sound of your issue, I think there’s a funky temperature sensor somewhere in that is sending poor information to the transmission control module. The overtemperature info it is receiving is making the control module return a shutdown code because of overheating.

With that said, the diagnostic that I asked you to have run should indicate the proper sensors — there may be more than one — to have replaced.

I don’t think you have to have the transmission replaced at all. You can if you would like to invest $3,400 or so, but you would be wasting your money. Have your technician track down the offending sensor packs and have them replaced. You will save yourself thousands as each sensor pack is about $400 with parts and labor to replace.

Since I think it’s only limited to one sensor pack, perhaps two, I believe you will save yourself on the order of $2,600. That’s enough for you to buy me an ice cream cone. I like chocolate chip, thanks!

November 2, 2016 at 10:43 pm in reply to: 1999 Dodge Caravan oil leak and hesitates before going in gear #7687HostgatorMemberI think you have two problems that are both related to the transmission. In your first example, you indicated the van drives fine but when you come to a stoplight, it shudders a bit when you are taking off down the road. And, then you say you see red stains underneath your minivan.

For starters, I think that, at some point, your transmission was overfilled. You may think this is okay, but it isn’t. The transmission is made to run with — depending on the type, clutches and the like — anywhere between three and six quarts of transmission fluid — most use five.

Each transmission has certain pressure parameters to work correctly. In other words, if your transmission normally runs with five quarts of fluid, it might be running at say six pounds per square in inside (don’t hold me to the exact figures here because I’m describing how things work). If you add an extra quart of fluid, you are adding to the pressure load. In other words, the six pounds may now be nine or 10 or so.

At this level of pressure, the various parts don’t work correctly. In fact, they are forced to work against pressures that are too high and, in some cases, parts that should be open are closed and vice versa. At this time, damage begins to accumulate in your transmission.

I speculate that this is what happened to your tranny. Unfortunately, it is too late to do much about it now.

Because the pressure was too high, I think the torque converter and impeller blades have been damaged as have the clutches and bands. The result is the type of whirring style delay you mentioned.

The only cure for either problem is a rebuilt transmission. If you plan to keep the Dodge on the road and it is in good shape — it is 17 years old, after all — then you will have to make the investment of about $3,400 to replace the current transaxle with a rebuilt. Be aware that the overpressure may have forced the output shafts out of true and they may also be damaged so it is something else to think about (you may not notice the problem as your transaxle (transmission) is used to dealing with output shafts that aren’t true so it performs in a way that feels right to you).

As to the second issue, it is related to the first. Since your transmission has been overfilled, seals may have weakened or blown out. Those seals are on the input and output shafts as well as around the transmission pan.

I suspect that if you look under your transmission you will see transmission fluid dripping from the bead edge of the pan.

Again, there’s major damage here that has to be repaired.

Frankly with what you have described to me, maybe it’s time to think of turning in your old ride on something a bit newer. There are great deals around on 2005-10 minivans that offer a lot for the money. I know it isn’t what you may have hoped to hear, but I am being honest. Let me know what you decide.

October 29, 2016 at 6:22 pm in reply to: 93 Ranger won\'t move when shifted into 3rd or 4th gear #7681HostgatorMemberI hate to say this as I like that version of the Ranger myself (it was cool), but, maybe it’s time for a newer pickup. My own gut feeling is that the dogs that are supposed to mesh with each gear are somehow coming up short, most likely because of wear. With that said, you may have trouble finding the parts you need to fix things.

Dealerships and major shops don’t keep car parts on hand after 20 years. You have to go to a specialty supplier and they tend to be very expensive. And, I do know that you have done lots of work yourself, which is great, but, at this point, I suspect that some of the parts you have installed aren’t correct and they may have worsened the problems you are having. The problems could be at the point where it just doesn’t make any more sense to try to fix this. I would suggest cutting your losses on this and finding a newer, less burdensome replacement.

HostgatorMemberI know this your dealer has probably tried this, but, are you sure all of the transmission cooler lines have been run and checked. If there is one thing that your transmission does it is create lots of heat and that heat has to go somewhere. That is why your transmission has its own lines into and out of the radiator core.

One of those lines may be crimped up behind a piece of the undercarriage that your technician may not see. If that’s the case, then there’s no coolant circulating in the jacket around the tranny and the result is overheating and failure. It is also possible that the lines may not be caught and crimped but may just be collapsed inside an armored runner. If you look around the surface of your transmission it is more than likely that you will see several armored hoses. The reason for the armor is pretty evident. If you take your pickup to a worksite (supposing you are in the building trades) and your undercarriage hits, but doesn’t hang up on rock, the armoring protects the heating and cooling lines to the transmission’s waterjacket. Without armoring, the rock could just as easily have torn up the cooling line, which is the reason for the armoring.

The armoring is great but it does mean that if a line collapses, as was mentioned, you would never find it or even think to find it. Have your tech run all of the cooling lines into and out of the transmission jacket to make sure there are no collapsed lines inside the armoring.

Now, let’s suppose that your pickup has a secondary transmission cooler installed because you do lots of hauling (I think you mentioned you were trailering when the problem occurred). One of the recommendations that I would have given you when setting up your truck — I used to help people set up and buy trucks for a dealer — is to be sure that you have a separate tranny cooler installed. It’s like a special radiator dedicated to the transmission and helps keeps things cool so your transmission fluid doesn’t overheat and possibly boil away, leaving you high and dry.

Now, assuming you have the transmission cooler installed, has your technician checked all of the hoses going to and from the tranny cooler. Again, all it takes is one crimped or pinched line or a collapsed line to shut things down. If it is in an unnoticed area, then your technician may never notice it. Let me know what happens on this one, please. I want to see you get your pickup back soon.

HostgatorMemberAren’t electronics wonderful? Yes, they let us run transmissions right on the edge between great performance and the black hole and they can keep up that knife edge dance for a long time, but, when there is a condition that upsets the fine balance, your engine or transmission can spin off in to Never Never Land without so much as a “By Your Leave.”

Here’s what I think happened in your VeeDub’s case, I believe the transmission control module may have gone west. The transmission control module (TCM) monitors multiple systems through sensors and relays, directing each transmission subsystem to act when it is supposed to. Normally, this functionality happens in the background and you accept it grateful to have it.

However, if the TCM goes, your transmission loses its ability to think and since it does, it can’t react to the orders that the engine control module may be sending out. Again, the result is a big empty as the vehicle doesn’t move ahead.

I’d suggest you have the Jetta towed to a service area or independent transmission shop and have the technician perform a diagnostic with an OBD-II scanner. That scan should narrow things down to the basics and give you the reason things aren’t working.

Here’s something you might try yourself while you are waiting for the tow truck. Open up the hood and look around for any plastic white connectors that have multi-colored wires on both sides. This is just a hunch, but it possible that a connector that powers the TCM may have worked loose is causing your problems.

HostgatorMemberIs it flashing in any sort of pattern? If so, could you check the pattern and right down the numbers that it spells out? I can help better then.

Quickly, off the top of my head, I would have to say, check the interface wiring, first, between the transmission control module wiring harness and the engine control module. They both should be wired into a common bus that likely contains other major internal automotive systems. This is part of the CAN or Car Automotive Network also known as the Internet of Cars (IOC). Automakers are letting devices across your car talk through the CAN and if one system is left off the wire, so to speak, it won’t work.

In your case, somehow, I think the transmission control module has been left out of the picture and if it has, your Kia won’t move. Have your technician check into that. And, while he’s at it, have the tech put an OBD-II scanner into the diagnostic port to run down the exact problem and fix it.

Please let me know if this helps? And, let me know the results of the blinks on the Hold light.

October 24, 2016 at 3:36 pm in reply to: 93 Ranger won\'t move when shifted into 3rd or 4th gear #7665HostgatorMemberI was in the garage last night shifting throughout the gears and it was going into the 3rd and 4th everytime. I would check it by trying to move the truck myself physically and it wouldn’t. I got excited and decided to go and take it for a spin. I thought it was fixed. This was after gravity bleeding the slave by the way. I go to drive it and once again go to shift into 3rd gear and once again NOTHING! On top of that I was forced to leave my truck down the road because the pushrod ended up breaking somehow along the way. I’m about fed up with it at this point

October 24, 2016 at 3:29 pm in reply to: 93 Ranger won\'t move when shifted into 3rd or 4th gear #7664HostgatorMemberI would check again. Unless the five-speed is connected physically by the linkage, there is usually a shift cable and adjustment. If not, the problem could be in the dogs that are released and then take up again when you shift. I’ll research it a bit myself and see what we both come up with.

October 24, 2016 at 1:46 am in reply to: 93 Ranger won\'t move when shifted into 3rd or 4th gear #7663HostgatorMemberI was just looking through my Haynes manual. There is no mention of a shift cable with the 5spd transmission

October 24, 2016 at 1:38 am in reply to: 93 Ranger won\'t move when shifted into 3rd or 4th gear #7662HostgatorMemberI will have to try that. Not really sure how to access the shifter console but I can figure it out. Thanks for the response. I will let you know shortly

October 22, 2016 at 5:57 pm in reply to: 93 Ranger won\'t move when shifted into 3rd or 4th gear #7661HostgatorMemberThis may seem like a simple thing to overlook, but, you have told me you have replaced most of the transmission but I don’t see anything about the shift cable. Did you check the cable inside the runner to make sure it is just too stretched out to enable the dogs to catch in third and fourth.

If the cable is stretched too far it will bind so that in the lower gears it may be fine but when you are shifting into third and fourth the cable starts to bind because it is just a tad too long.

Why might it be happening with all the work you have done? It’s simple! Because you can’t see easily inside the cable runner to look at the shifter wire (it’s about a number 14 multiple strand steel cable), you can’t see that it might have stretched. However, the way it is acting tells me it is.

If you know how to do it, I would suggest going into the shift console, finding the adjustment nut — usually a knurled passthrough-style nut — loosening it a tad and taking some of the slack out of it. You will need two pliers to take care of this. Place one at the nut and a second just in back of it and apply pressure to the outboard pliers. Once the cable begins to slide out, pull it until all of the slack has gone out of the cable — it should only be a matter of inches — and then clamp the cable tightly at the nut so it won’t slide back in. Finally, tighten the adjustment nut finger-tight to complete the procedure.

I think this should cure your problem.

Let me know if this fixes the problem. I’d like to find out.

HostgatorMemberMy thinking is this: take whatever money you can and invest it in another ride. If you were to put in a new tranny you will never recover the cost. The fact is you will be behind the eight ball on this one by by about $2,400 or so, if you put in a rebuilt. Because of that fact, it doesn’t make much sense. So, the best way out is to either advertise it “as-is,” asking for about double — $1,600 — to pay for your advertising and other costs. The other way is to put an ad in the local shopper; listing a reasonable asking price (where you will get all your money back for your investment in the Honda), and the waiting.

I would list it as an auction on eBay, set a reserve of about $1,600 and then let it go for a week or 10 days to see what the maximum bids are. I am willing to bet you a box of coffee (I like mine regular with milk and sugar, thanks) that when the bidding is over, you have made your price plus some extra.

The only things I wouldn’t do right now are: 1. sell it to a wholesaler or scrap yard because, as you say, you will never get your money out, and 2. put in a rebuilt tranny because you’ll be losing money.

I know I answer questions about transmissions but I have to also be honest with you and that’s my best advice. If the Honda were a bit newer or in better shape, then I would be urging you to invest in the tranny as the Honda will be set for another 200,000 miles (there is a member of my family who picked up a “new” car a couple of years ago — a Honda with nearly 400,000 miles on the odometer — he’s still driving it to work and on family vacations so you can see why I gave you the last piece of advice).

HostgatorMemberHere’s a thought, why not sell it as-it? Of course, you will have to disclose the problems with the transmission and you will have to adjust the sale price, but, you won’t have to invest the $3,200 you will have to put into the transmission to make things right.

From what you have told me, the transmission is no longer among the functioning. I would bet dollars to doughnuts that, among other things, the transmission’s:

- Torque converter is gone

- Impeller may be shot

- Valve body may have problems

- Solenoids are shot

- Clutches are gone

- Bands are probably gone

- Transmission control module

Frankly, the only way you can sell your car is either by handling the way in which I suggested or you can fix it — investing the $3,200 you would need to get it rolling again — and hope you can recoup your investment. There is no way of knowing whether you can sell it for a price that would get you the money you have put into it back. The choice, of course, is yours but if you were to ask me what I would do, I would go with selling as-is.

HostgatorMemberThere are a couple of recurring problems that affect Uplanders built from 2005-08. They range from a service bulletin that covers stalling problems similar to the one you are experiencing to valve body problems to dirty transmission fluid.

Briefly, the service bulletin addresses stalling issues that are similar to the one you experiencing in your Uplander. Honestly, it does apply to other parts of the engine, but, there is a mention of the transmission in it so I thought I would add it to the list of possible cures.

My suggestion is this: take your car to a dealer’s service area and ask them to look up all of the service bulletins that apply to your Uplander. If it is a dealer you have used for a time so much the better because the dealership will have a long record of the service procedures performed on your minivan.

There are four technical service bulletins that apply specifically to the transmission. They are:

- 08-07-30-016

- 08-07-30-002

- 08-07-30-013

- 4133 (believe it is internal number)

I won’t go into each bulletin as we have space constraints, but, suffice it to say, one or another of them may apply. The only way to know is to have a technician check.

There have been reports of dirt in the valve body that keeps the check valves from working properly. If the check valves don’t open in sequence, you will find your Uplander either not going into the gear you select, at all. Or, it may act as you have described. If this is the case, a valve body cleaning will put it into shape. It should cost about $450 for the work.

Finally, it is possible that your Uplander is either very low on transmission fluid or dirt has built up in the fluid and it has left deposits on parts of the transmission that are keeping it from working correctly. Also, the dirt may have plugged the transmission filter which stops fluid flow — or cuts it down significantly. If this happens your Uplander won’t budge.

I don’t think your Uplander needs a rebuilt installed — the price range is spot on, by the way. However, it does need work that, in some cases, might tip $800. I know your money is tight and that you may not have the funds. However, at least it is not $3,000 or more. Let me know what happens, please and we will try to figure things out.

More information here on the Uplander:

HostgatorMemberTwo thoughts come to mind with your transmission’s symptoms.

- A sticking solenoid

- An intermittent in one of the sensor clusters

In both cases, honestly, there’s something shorting somewhere that is causing the problem.

The first place I would check is the solenoid cluster on and in the valve body. The good thing is that at least one of the solenoids is on the outside of the valve body so it is easily accessible. The not-so-good thing is that your technician will have to do a partial transmission teardown to access the innards of the valve body. If it seems like a bit of overkill to have the solenoids split like that, I agree. However, it is understandable in light of the fact that the solenoids were likely added one-at-a-time over time. This has given them the odd placements.

Placements aside, it does sound like one of the solenoids is sticking. To test it, your technician should put a small current into the positive side of the solenoid. Every time he applies the current, the solenoid should click on. If it does not, say, after 10 good tries, you have found the culprit.

Replacing a solenoid is the least expensive major service. It is a major service because it requires a partial teardown of the transmission It should cost about $150 for parts, although the labor is somewhat big if your tech has to go inside the valve body. Overall, labor should be about $550.

The other possibility is a short in one of the sensor clusters. By the sound of it, it could be — and most likely is — the throttle positioning sensor. The throttle positioning sensor tells the transmission control unit whether your vehicle is accelerating or decelerating from the force you apply to it.

If the throttle positioning sensor is shorting, telling the transmission control unit a bit of misinformation, it is very likely that you will experience the performance you are describing.

Let’s say that the throttle positioning sensor is okay, where else could the problem be? More than likely it is somewhere in the electronic cluster that control the transmission. Since the tranny may have eight or more sensors working, at any given time, and since some of them may even be within the engine bay, rather than the transmission, it will take time to track things down. However, if your technician has patience, he will find the answer, now that he has, at least, a suggested direction for hhis investigation.

HostgatorMemberThat’s the first place to start. I’d have your service tech completely drain the transmission, replace the filter and then refill with the proper fluid (Dexron, is the one I think, but make sure). Be sure that the tech removes the tranny pan lid so that the half-quart or so that is left in the pan is removed from the transmission as well.

Once the fluid is replaced and is at the correct level — double-check this with the dipstick — with your foot on the brake, run the Monte through the gears with your foot on the brake to keep it from rolling. This move is to make sure the fluid gets into each gear correctly.

Next, check Reverse and I think you will be pleasantly surprised that it will work correctly. You see, if a transmission is overfilled it is nearly as bad as being down a quart or so. Since the transmission depends a fine internal pressure balance, if it is too full or if there is not enough that balance is upset and the tranny works harder than necessary.

Even though it is working harder, in either instance, the work doesn’t translate into better. If there isn’t enough fluid, the transmission tries to overcome deficiencies by building up extra pressure trying to push fluid into the spaces it is not getting to because there isn’t enough. At some times, it succeeds and everything seems to work okay, while, most of the time, the transmission slips.

If the transmission is overfilled, then an over-pressure condition is created. This can lead to damage because the transmission fluid is moving with too much force. In this instance, parts like the torque converter, turbine and impeller blades, clutches and bands and even the gearing can be damaged.

It is quite possible, if there is too much fluid, that gears won’t engage at all, giving you the problem you have.

One other important thing to do is have a diagnostic performed. Have your technician use an OBD-II scanner and the proper software to determine if the tranny is throwing error codes to the engine control module (ECM), the Monte’s primary engine computer. The codes are stored there.

It is quite possible that the control solenoid(s) for reverse are shot and that is why your Monte isn’t going into reverse. This will be revealed by a diagnostic. The good news here is that replacing the solenoid or are relatively inexpensive as the solenoid, itself, costs about $175. The labor is the feature that raises the cost to about $550 for both solenoids, if they have to be replaced.

Let me know what happens, I’d like to hear.

HostgatorMemberTo ensure that your last question doesn’t happen — damage — my first suggestion is this, take your car to your Honda dealer and have his techs take a look. They are the people most experienced with handling Hondas (or they are supposed to be), so it makes sense. It is true that you will find dealers tend to be the most expensive service areas, however, they do make up for that expense in an important area — return warranties.

Yes, most service areas will give you a service warranty where they will continue to work and attempt to fix a problem. But — it’s a big but — there comes a time when an independent shop may throw up its hands and say go to your dealer — not a great endorsement of some independents (it’s not all of them, by any means) but it is nevertheless true.

Dealers, on the other hand, while, as noted, expensive have to keep on working the issue until they fix it. There are a couple of reasons they do this:

- Public relations: Imagine what would happen to a dealer’s reputation if his mechanics said after a couple of visits: “Take it elsewhere for repairs, we can’t fix it!” The dealer’s reputation would be in tatters quite quickly especially when Social Media gets their hands on it. They will have a field day.

- Reputation: It may seem like this is a repeat of the first note, but it isn’t. A dealer’s reputation and customer service reputation is what sets it apart from other dealers. If they blow it, it will quickly be spread far and wide. However, if they work the issue and solve it — which does happen, eventually — then they gain bragging rights and enhance their rep.

Getting back to your central issue, your tranny’s poor performance. The Drive light flashing means that the Transmission Control Module (TCM) is reporting an error the the Engine Control Module (ECM) continuously.

There are two likely reasons it is on, the torque converter is having issues or your transmission is down on fluid. Of the two, I think the most likely is that your transmission is probably down a quart or so.

You can have the dealership perform the work — they would be glad to do it — or you can do it yourself.

We have information that will help you at Checking Your Transmission Fluid Level.” Take a look at it and see how you can measure the level of your Odyssey’s fluid. Don’t worry about the steps in replacing the fluid because you won’t be doing that.

It should take care of your problem. Let me know what happens as I like to hear from my readers to see if there are followup issues.

-

AuthorPosts

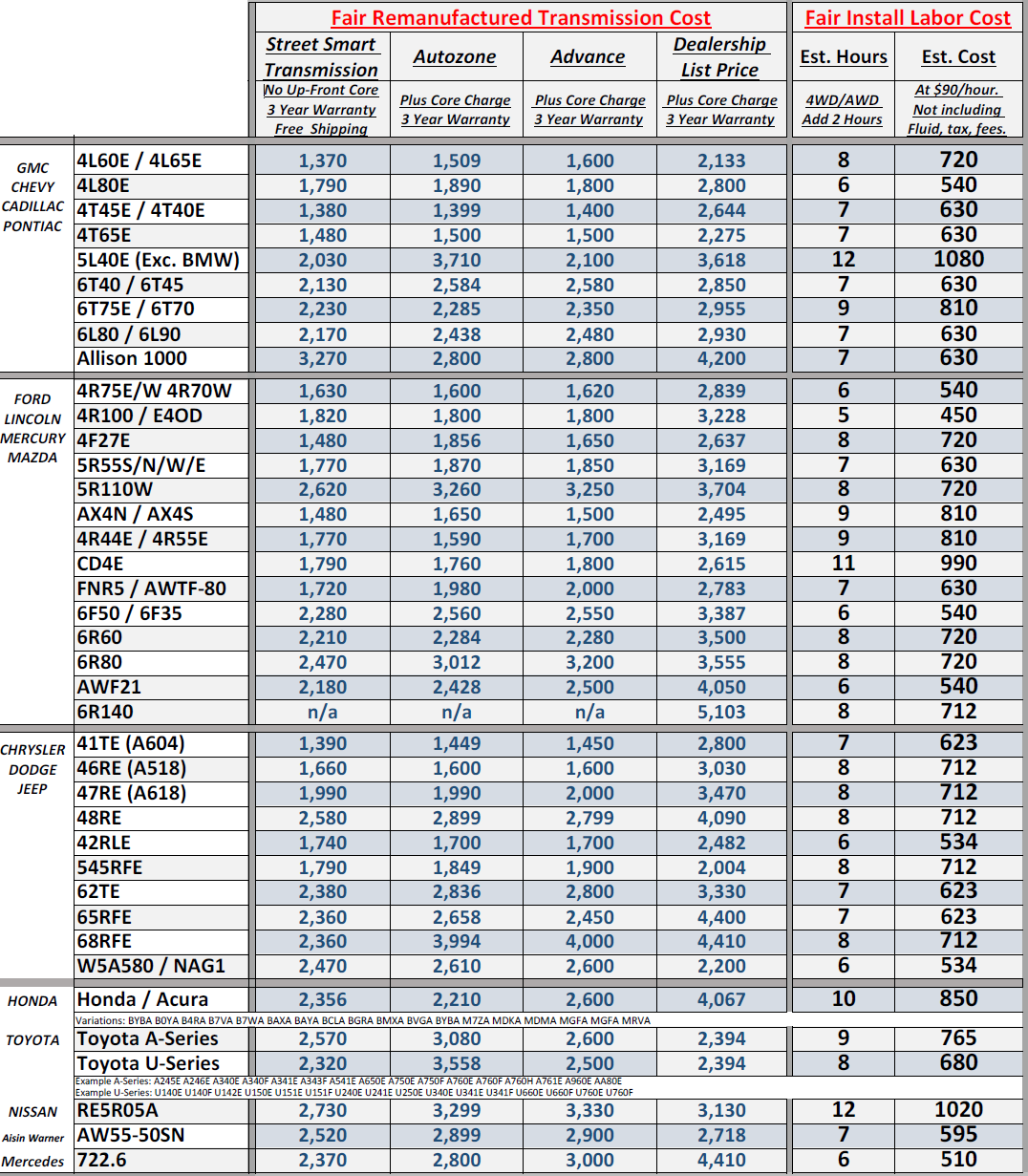

Fair Replacement Transmission Cost by Vehicle

- Use the Year / Make / Model lookup tool to determine what transmission your vehicle has. [transtar]

- Find your transmission model in the table below for fair prices from reputable suppliers. Also fair labor cost for local installation at a local auto repair shop.

- Get a free estimate on a remanufactured transmission by email.

Fair Remanufactured Transmission Price Ranges by Transmission Model Updated May 1, 2018