Forum Replies Created

-

AuthorPosts

-

HostgatorMember

You have two or three choices in the diagnosis of your problem. The most obvious issue — and the one I think it likely is — is that the transmission is shot. If your Audi stays running when you let out the clutch and doesn’t move and doesn’t stall, then, your gears aren’t engaging so I suspect that the transmission is, more or less, fried. With an Audi, you are looking at a $4,000 replacement bill — they are very expensive to repair.

There are other things you might look at. Here’s a list:

- The throwout bearing is shot. This is the device that disconnects the clutch plate from the plate on the engine side, allowing you to shift. If the throwout bearing is gone, then your Audi will sit there and not move, even though you shift into gear. The Audi won’t stall, either, if you let the clutch out too quickly with too little gas. Repairs to this are in the $1,500 to $1,800 region.

- The clutch and clutch plate are shot. If this pair is gone, then, your Audi will act as you describe. Repairs to this pair is in the $1,500 to $2,200 range.

- The gears are shot and slip in and out too quickly to have any effect. This is another major repair that is in the $2,200 range.

- The pressure plate is shot. This is the device that keeps the clutch plate flat against the flywheel on the engine side. The alignment of this plate is critical for proper tranny operation. You are looking at a $2,200 bill, minimum.

I could go on and on but I think your best move is having your technician install a rebuilt transmission and parts. You will be better off in the long run. It is true that it is expensive, but, depending on the cost of your Audi, it is still less money than a new vehicle.

Need a replacement transmission? Quality transmissions are hard to find. Free estimate to your email.HostgatorMemberWhen you are switching transmissions, the whole unit is swapped out and a new one is put in its place. Of course, the solenoids are swapped as well. It doesn’t make much sense to change out a tranny and not change the solenoids. If the one of the solenoids was bad — there are two on the Tiburon — then the issue won’t change if you just swap the transmission out and leave them in place.

HostgatorMemberThanks for stopping by, I appreciate it. I have a question for you: could you tell me the issues you for which you are looking answers?

HostgatorMemberYou’ve done a pretty good job so far of diagnosing the problem. However, the results of the 0700/0741 combination will probably surprise you. It shows there is an electrical/electronic problem and not a mechanical one (by the way, diagnosing and replacing the bad range sensor will save you from other problems once you have the problem we are discussing solved.

With that said, a little background will keep things clear for you. In all transmissions built since the early 1990s (and before) there are little workhorses called control modules, whose function is to keep things running correctly and recording errors, working in the background. Unless one of the modules goes out of whack, you won’t even know they are there.

The control modules have other names that are probably more recognizable to you. For example, the Transmission Control Module (TCM) and Engine Control Module (ECM) are better known as microcomputers. They are the computers that control the transmission, of course, and all of the many subsystems that are required to meet the tight tolerances for emissions and mileage that cars and SUVs have to meet today.

In the transmission, there is one module, the Torque Converter Clutch Control Module (TCCM) that controls the torque converter. The torque converter is a device that balances the torque forces for the engine and transmission. In a manual transmission, you control the balance by accelerating and increasing the torque from the engine so that it matches the torque requirements of the transmission with the clutch and gearshift. The TCCM handles the same process in an automatic. It balances the engine’s output requirements with the transmission’s input requirements so that the vehicle doesn’t stall. Eventually, the Clutch Module takes over and locks up the transmission so there is a solid lock between the transmission and engine (similar to the top gear in a manual when you are finished running through the gears).

In an automatic transmission, there are a number of clutches (and bands) that engage as it goes through its gear train. In order to engage properly, a solenoid (Transmission Converter Clutch Control Solenoids) fires when the engine reaches the proper rotational speed (also known as revs or torque) so that the proper gear engages.

In cars of the 1990s, which were generally four-speeds, there were two solenoid actuator packs, one on the inside of the valve body and other on the outside. One of them controlled two gears and the controlled the other two gears (for example, solenoid-1, switch-1; solenoid-2, switch 1, first gear; solenoid-2, switch-2, solenoid-2, switch 1, second gear, and so on). Today’s transmissions (your 2007 was a five-speed, so it still relied on two packs as they could carry five gears) rely on multi-clutch packs and solenoids so that a six-speed, uses three solenoids, while an eight-speed uses four, and so on.

With all that as background, your Sportage has a problem with its solenoid packs. It could be with one or with two. From the sound of it, I think you have two bad solenoids that have to be replaced. Once you have repaired them, you will find your Sportage shifts and operates normally.

If you feel confident taking your Sportage’s transmission apart, then you can purchase both solenoid packs for about $300 and do the work, very carefully. Since you do have to tear down the transmission to get the valve body cover off so you can access, if you have the least bit of doubt, let a transmission shop handle the repair because they have the expertise to do it. It will cost you about $700 to $800 to have the repair done.

By the way, the reason your Sportage is sitting in second or third is because it is in limp-home mode. This enables you to get your SUV to a service area or home. The single-gear setting give you just enough performance to get where you need to go.

Please let me know what happens, I do want to hear it.

HostgatorMemberBelieve it or not, your Mustang five-speed uses synchros, though the action of the gearshift is still somewhat heavy — I guess it’s to remind you of the days of the old Hurst shifters with their long throws, double-clutching and heavy action — there are still synchronizers on every gear (synchros are spinning sleeves that ensure that when you shift, everything lines up correctly when you shift and everything slides home smoothly). When you worked on the gearshift, even though you fixed the problem with the lockup and clutch, I suspect that the synchronizers were thrown out of synch so that now when you shift they are clashing with the gearing, causing the shift to pop out, losing the gears.

I would look closely at the synchronizer assembly chain — you can find the chain in a service manual — checking the synchro for each gear and its related mechanical pieces so that you can make sure that they are all in alignment before you button things up.

Once you have checked them, take it out for a drive and run it through the gears and I suspect you will find you have solved the problem. Let me know what happens.

HostgatorMemberYou are in luck. We have a tool that will help you find the transmission in your 1500. Use this link and then follow the steps outlined. https://www.transmissionrepaircostguide.com/what-transmission-do-i-have/.

HostgatorMemberThere are three possible issues with your Fusion’s transaxle. The first is in the clutch/band packs; the second could be in the valve body, and the third could be a sticking solenoid. All of them mimic the operation of the others, though, they are very different.

The clutch/band packs are the devices that enable your Fusion to go through the gears in the proper order. As the transmission spins up to match the engine speed, the proper gearing is chosen and the proper clutch/band pack comes into play. If the device has been damaged or is excessively worn, then it may grab and clunk into gear as you describe.

If there’s a problem with the valve body, your Fusion will act in the same way. The reason it is likely happening is that the valving that is controlling the flow of transmission fluid to a gear may be sticking and the result is that the Fusion’s transaxle thuds when it goes into gear. The checkvalves within the valve body are little more than lightweight ball bearings that float in a partial enclosure that is held open by a light-pressure spring. In action, the fluid is directed to a specific gear and the pressure in the channel is kept low so the valve remains open; other channels have their pressures increased to they close. The added pressure presses the ball bearing against the spring, halting fluid flow. If the spring becomes worn, it can let the ball bearing bounce within its enclosure and the transmission will clunk into gear.

If the gear selection solenoid packs stick, then the action is the same. Each gear is controlled by one of two solenoids on or in the valve body. The way the solenoids are activated determines which gear is being chosen. For instance, solenoid switch 1 on solenoid 1 may select first gear, while solenoid switch 2 on solenoid 1 may choose second. Solenoid switch 1 on solenoid 2 may choose third, while solenoid switch 2 on solenoid 2 may choose fourth. To switch to fifth, solenoid switches 1 and 2 on solenoid 1 may activate; while sixth would be indicated by activating solenoid switches 1 and 2 on solenoid 2. Reverse could be indicated by activating all of the solenoid switches or leaving them open. If one of the solenoid switches is slow or sticky, then your Fusion will operate as you describe.

To find out the problem, you are going to have to take your Fusion to a well-equipped full service transmission shop where they can run a full set of OBD-II diagnostics to determine and repair the problem. The cost of the repair will vary with the device, but, in general, you are looking at spending between $800 and $1,800.

HostgatorMemberHere’s my take on the problem: from what you have told me (thanks for all of the detail, it helped), your transmission could have any number of problems. Yes I know this looks like a cop-out, but it isn’t. Look at the list of possible problems:

- Torque converter — pump, turbine and stator

- Clutches/bands — without them your motorhome won’t move

- Planetary gears — needed to enable the right gear selection for driving conditions

- Hydraulic system/valve body — ensures the fluid gets to the right gear at the right time

- Input shaft/output shaft — as the names imply they take power and deliver power to the drivetrain

- Electronic systems — since the 1990s, computers have replaced many mechanical actuators and systems because they are faster and more accurate; this includes the sensors such as the throttle position sensor(TPS); the mass airflow sensor (MAF); manifold absolute air pressure sensor (MAP), and the like

- Computerized systems — yes, there is overlap with the last topic but there is a subtle difference and it is that the number of “control modules” (computers) such as the transmission control module (TCM), engine control module (ECM) and the like that may either operate directly in the computer or touch it in some way. By the age of your motorhome there were likely eight computers systems that either dealt directly with the computer or touched it in some way

This is only a partial list of where there may be problems. Yes, you could try with the throttle positioning sensor, but, then you would have to start dealing with the other sensors such as the MAF and the MAP and solenoids, as well as the other control circuits themselves. And, then there are the control modules involved. Which ones might be bad?

What I am saying to you is that I would advise you to take the motorhome into the dealership and let them work on the transmission. Be prepared for some sticker shock, though, because you will likely be spending the better part of $4,000 to make sure the job is done correctly. The good thing about this investment, though, is that you will have a warranty available after the work is done so that if there are other transmission problems, you are covered.

Oh, and my thinking on the problem you described began when the former owner overfilled the transmission by two quarts. The pressures that build up in the transmission and the added pressure exerted by the extra two quarts likely caused many of the problems you motorhome is facing. For example, the blades on the turbine are rather delicate and they could easily have been damaged. The same is true of the checkvalves in the valve body and so on.

Let me know what happens, if you would. I am interested.

HostgatorMemberIn the first question, you state that once one of the clutches was replaced in a dual-clutch Ford Focus, the engine runs roughly, trembles and shakes. You also say there’s no check engine light or DTC.

There are several possible causes of this issue. First and foremost, I’d take the parts out again, noting the order in which everything comes out. Then, I’d check the service manual to see if there might be a part that was inserted incorrectly or which might be missing.

It is very simple, given the complexity of the clutch assemblies, to insert a part on the wrong side or a part that might just be enough out of true to cause the engine to tremble. I’d also check closely to see if there might be a part that is missing. If the clutch isn’t taking up correctly and slipping, for example, then the engine would jitter and judder when the Focus was in gear.

And, no there might not be a check engine light because, you noted everything seemed to go together smoothly. In this instance, it is possible that the Engine Control Module (ECM) or the computer that catches all the codes is not catching any codes from the clutch assembly and therefore there is not check engine light.

My suggestion — yes I know I suggested pulling the new assembly and reinserting it — however, the real fix for this is try another clutch assembly, carefully inserting it following every step and rechecking every step. (What you are really talking about here is the clutch actuator, a small motor that ensures that this particular half of the dual-clutch assembly works. I think once you have replaced the actuator assembly, you will be on your way, so to speak).

Onto the other issue — both are related — the first code, P090c, indicates there is low voltage from the B actuator. Since there are two actuators or actuator motors, more correctly, if one of the pair is showing a low voltage, then it means that the particular actuator isn’t working correctly and should be replaced. In this case, it is the B actuator that is showing the low voltage. This is the P090c.

The p2837 code has also been thrown to the ECM because the B actuator is bad. As noted, there are two electric motors that are used today to shift the gears. The work with the solenoids to ensure that the gearshift works correctly. One of the actuators controls gears 1, 3 and 5, while the other activates Reverse, 2, 4, and 6. Gear shifting occurs when one of the pair of shift drums, connected to the shift motor pinion by two ideal gears is activated as it is called on to shift to a specific gear. Though the motors are, in a sense, integrated within the transmission, they are only connected at the electronic level as they are integrated in the Transmission Control Module (TCM). However, they work independently (which makes sense as they choose different gears at different times to keep things working correctly).

The actual error reads as an error in the shift fork B position circuit range or performance. The check engine light will illuminate.

In any event, the B “shift fork” or actuator must be replaced if you receive this error code. Once it is replaced, your Focus should be fine. Given the position of the actuator/shift fork, this repair, with parts and labor, will cost between $1,400 and $1,800.

HostgatorMemberWhat you are hearing is very much the truth. When a transmission is pulled out of a vehicle, unless it was done by the manufacturer, then, the transmission still believes it is in the original vehicle.

Now, I don’t know why the BMW dealership didn’t have the reset codes. However, it is possible your BMW wasn’t serviced by the dealership or wasn’t sold to you by them, they may not have had much incentive to reprogram yours.

It also is pretty indicative that this might be the case because they sent you to a technician who was said to know how to unlock the transmission but it turns out that he couldn’t do it.

Now, I don’t think the dealership will ever tell you that this is actually the case — it wouldn’t do their reputation or business much good if they let you know this was the case.

Unfortunately, you are in the middle here and, unless you want to drive your BMW again, then I think you don’t have much choice in what you have to do.

HostgatorMemberHonestly, I have to agree with the technicians. From what you are telling me, it seems that one or more of the synchros on your transmission may need to be replaced.

Before synchronizers were invented, if you drove a standard transmission, you had to rev the engine before shifting to the next gear so that you matched the engine speed and transmission as closely as possible.

Otherwise the gears would grind and you ran the risk of a stall.

Synchros, on the other hand, allowed each gear to spool up automatically so that the gearshift and engine speeds were matched fairly well and you could shift gears pretty effortlessly. There was no more worrying about double-clutching and the like. By double-clutching and revving, you manually took care of what the synchronizers do automatically.

Synchyros are essentially sleeves that automatically spin so that each gear spins at the proper speed so that the engine and gear synchronize automatically. This is what makes today’s transmissions such a pleasure to shift.

HostgatorMemberThe answer to this is pretty straightforward. Before, say, 1990 as digital electronics became more refined, a series of gears and other mechanical features chose a specific gear, once you chose the gear you wanted to access with your gearshift selector.

There was a problem with this. As transmissions were called on to become more exacting with regard to upshift points — due to emissions — mechanical means of choosing gears just couldn’t cut it. If you needed a certain engine speed/tranny speed combination to maintain emissions, the mechanical way of doing things just couldn’t cut it. Vehicles couldn’t meet the more exacting shifting standards that were needed to meet emissions requirements.

Enter the digital computer system. While microcomputers were being used as engine control modules (ECM) or transmission control modules (TCM), giving a greater measure of control, there were still areas where mechanical features were used.Taking advantage of the greater precision offered by solenoid (switch) technology, the automakers opted to use solenoids to control the gearing chosen.

Using solenoids allowed greater precision in gear choice with regards to engine speed and transmission matching so that emissions control could be more precise.

Usually, they opted for two solenoid packs, one on the inside of the valve body and one on the outside, to set gearing. Each solenoid controlled two of the gears. For example, let’s say solenoid pack 1 switch 1 and solenoid pack 2 switch 2, put you in first gear, while pack 1 switch 2 and pack 2 switch 1 represented second and so on. Each gear was represented by two switch settings.

When those solenoids fail, you can no longer shift, other than mechanically as you state.

So, you are either going to have to do it yourself or take the pickup into a service area where the two solenoids will be swapped out and replaced. I think this will solve your problem. You are lucky as this is one of the more modest repairs costing about $600 — give or take a little — for parts and labor and materials.

HostgatorMemberHere are a couple of thoughts that should put you in the right direction.

Since I know now that your Civic has a manual installed, my first thought is to have the friction plate/clutch plate assembly looked at carefully. It sounds as if your Civic’s clutch plate is worn to the point where it is time the assembly should be replaced.

I know I called it an assembly and, in a sense, it is, since it acts as a unit. However, to be honest, the clutch plate is separate from the friction plate/flywheel assembly. When you push down on the clutch, the throwout bearing takes up the slack and separates the two plates so that you can shift to the next gear up or down. If you tried shifting without the clutch applied, then, assuming you have done this once or twice (I know I have), you know that your Civic would shudder and stop, unless you get the clutch in.

With that said, it is possible that the clutch plate is worn to the point where it is slipping in various gears. It may not be totally worn, but it is worn enough so that the clutch will slip and act in the manner you describe.

Now it is possible that it is on the engine side of the equation (friction plate/flywheel). If it is, then you will have to have the entire unit replaced, at a cost of about $1,200 or so for the unit without the $450 or so labor involved (there are so many Civics out there in scrapyards that you have the potential finding all the parts you need at a large savings in a local salvage yard where you will spend about 20 cents on the dollar — if it cost $1,400 new, it should cost you about $300 or so, though labor rates will remain the same).

It is possible that if the clutch face and friction plate/flywheel are in good shape, that the throwout bearing is shot. This means you will have to replace that unit at a cost of about $1,000 or so — with labor.

I’d look at those areas to start with and I think you will find it is likely one of those three.

HostgatorMemberOkay, I am assuming that your Civic has the automatic transmission installed because your description. in some spots, can be read either way. And, with that said, what you are experiencing is a simple case of “limp home-itis.”

Although you haven’t given me much to go on as to a specific diagnosis, I can tell that if your Civic revs and shakes when going from second to third and sometimes revs like it is in neutral then it is trying to shift into limp-home so you get home.

Now, it could be that the reason for the limp-home indication is that the torque converter is shot, however, there are other problems that can cause your Civic to act similarly. For example, if the tranny fluid is sludgy and dirty, it may not be able to pass smoothly through some of the hoses and galleries through which it has to go. In that instance, your shifts will be delayed and slipping.

It’s also possible that the bands and clutches have had it. Since it is happening through the range of the transmission, I would suspect that you’ll have to have them swapped out for all of the gears. And, if that is the case, then you are looking at a rebuilt transmission which will cost about $3,600, given today’s repair guides.

It is also possible that your Civic’s valve body could contain one or more check valves that have become lazy due to deposit buildups and because the springs have also become lazy. In this instance, your transmission will act the way you describe it.

Finally, one more thing that I can think of that might cause your transmission to act the way it is acting is that the shift-control solenoids are either sticking or failing which could cause the tranny to act in the manner you describe.

At this stage of your car’s life, given its age, I think you are looking at a rebuilt transmission. I hope this helps. Let me know if you have any further questions.

HostgatorMemberIf you have already dropped a replacement transmission into the Cavalier, why think about putting in another rebuilt? It may be that a couple of adjustments will fix things for you.

Here’s what I would suggest based on the 0730 error code:

- Contact the shop where you had the work done

- Ask them what their warranty period is on the transmission

- Ask them to retrace their steps on the replacement

- Ask them to redo the work so it is done correctly

Okay, so you are probably wondering why I am asking you to have the shop redo the work and it is a good question. I honestly think that when they reset the input and output shafts they somehow slipped out of position.

The 0730, as you might imagine, is a transmission error (07 pair is a giveaway). In this case, it is showing a variance in the rotations between the output and input shafts. This means the tranny will slip almost automatically, no matter what sensors and other parts you replace.

Indeed, this type of error can easily damage the clutch/band assemblies as well as putting stress on the gearing. You can see, then, why I am suggesting that the work be redone. Indeed, they should also replace any sensors or solenoids that also have to be replaced on their nickel.

Believe it or not, I am not slamming the techs who did the work because this is a rather tricky set up and it can easily be knocked out of alignment as other parts are replaced in the transmission as it is rebuilt.

If the shop won’t take care of that work, then I would suggest asking them to put a rebuilt in, splitting the cost with you as I think it is the fair way to handle things.

Please let me know what happens.

HostgatorMemberWith the information you have given me, I can’t honestly say you need a new transmission based on the 0700 error code you have given me. The 0700 code is called a generic. It sets a pointer to other problems that may exist in your transmission.

With the 0700 code, we have a good start. I need to know more, though. When the OBD-II tester listed the error code, there were probably some other codes listed with it. Can you give me the list of codes that were generated?

From what you have told me, I can’t really say one way or another whether you need a new tranny or not, until you get me the codes, that is.

If you can get me the list, I can help you a lot better.

HostgatorMemberYou have touched on a couple of points that are quite interesting. First, I would suggest that you take the Suburban into the shop so the tech can put it through its paces. I think that you may get some interesting results. Those results might indicate, for example, that there’s a failure with one of the control solenoids; or, it might also indicate that the solenoid stuck open briefly and reset when you restarted the SUV.

It is also possible that the transmission control module (TCM) may be registering a problem within the Valve Body, which is key to shifting. It is possible that the TCM is telling you that you have a sticking check valve somewhere within the Valve Body. It is also possible that it is indicating that the check valve should be replaced.

Check valves are little more than lightweight ball-bearings that are installed on lightweight springs. The combination of the light ball-bearing and spring make the system work because only increases and decreases in the transmission fluid pressure make the check valve responsive. If the pressure increases, the valve opens and allows the fluid to change its track from one gear to the next. When the pressure drops, the ball-bearing resets, cutting off the fluid flow.

I think your idea of having the tech check the SUV is great. It’s possible that the fluid could be down a quart or so and if it is your transmission will perform quite weirdly.

You also offer a suggestion that is quite valid, the SUV has to “learn” your driving style. For the last 25 years or more computers have been used in transmissions and related systems to provide for precise shifting and to help control emissions. Since your SUV only recently had its transmission replaced and since you purchased it from the owner who initiated the replacement, it is quite likely that your transmission has to become used to you and your braking and acceleration patterns.

Honestly, transmissions today are more about electronics than about mechanical systems. Indeed, the mechanical systems are, for the most part, fairly bulletproof. Yes, mechanical systems like the torque converter as well as the clutches and bands or the input shaft do fail. That failure, though, is pretty rare, all things considered.

Electronics, though, are another story. Think about the environment in which items like solenoids, sensors and control modules operate. The engine compartment is not electronics friendly. For example, your transmission’s issues may be have been caused by the solenoid glitches. Those glitches — brief outages or overvoltage conditions — could make your Suburban perform exactly as you described.

The obvious solution here is replacing the solenoid packs — about $175 apiece — which should fix this problem. It will only cost about $600 to replace the packs.

HostgatorMemberFirst and foremost drop the idea of a flush. When most tech shops perform a flush they do a high-pressure flush by putting a compressor line on the filler neck and then letting things rip. It is true that this will blast anything within the transmission cover out and into the pan. However, it is equally true that it may dislodge major deposits that have built up on, say, turbine blades or various surfaces. As the little chunks move around, they can damage some of the more delicate parts like check valves and such. Further, the chunks can become lodged in tiny galleries, causing heat problems or in the valve body valves themselves, causing shifting problems.

I can see where it might seem like the problem is in the solenoids alone. In fact, I can also agree that the diagnostic scanner would return the results that it returned. Further, if your tech has repaired Solenoids 1 and 2, the next obvious result codes you would receive, of course, would show that 3 and 4 have to be repaired.

However, I also think your technician is onto something with the valve body. You said that the Caddy hadn’t been driven in a year and that when you changed the transmission fluid it was black. Of course, that would be the case. However, that blackness also indicates a lot of dirt and possible buildups may be inside the transmission and when you keyed it on the first time, it is likely they spread throughout the transmission, resulting in problems that might not show up in error codes.

If the valve body has problems because one or more valves in a train of devices for a specific gear is stuck, it can force your transmission to mimic poor torque converter operation, which can also be indicated by the way your transmission is operating. Indeed, with the solenoid error codes, the valve body problem seems to make more and more sense.

With that said, I would have the valve body dismounted and thoroughly cleaned. I would also have the check valves either reset or replaced. I think that should fix your Caddy right up and you’ll be on your way. Let me know the results of this as I have some other thoughts, however, I don’t want to make things overly ambitious and costly for you. Like as not this will fix your Caddy right up.

HostgatorMemberAt this point, we will have to shift our focus from mechanical and other problems to diagnostic work. Both of the problems are remarkably similar: each vehicle has scream up to shifting speed before it will happen. This means that a sensor or control module is sticking and thus preventing the transmission from shifting correctly.

In order to determine where the problem is, you will have to have a complete diagnostic run of each vehicle with the proper OBD-II diagnostic software. The printout will point to the general area where the problems exist.

If you are lucky, Ford, whose diagnostic software is very detailed, will tell you exactly where the problems are and will then indicate the devices that should be swapped out or reprogrammed.

Once you have the results, be sure to have the proper sensors replaced (throttle positioning, quite possibly and maybe the Mass Air Pressure), plus a step-down sensor or two. This should cost under $600, while any reprogramming may add another $150 or so to the cost.

HostgatorMemberThere’s a linkage between the transmission and your accelerator that allows you to step down a gear so that you can pass other vehicles. It is much like the neutral-start switch that keeps your 1500 from starting until your foot is on the brake. Indeed, you can feel the linkage between the neutral-start switch when you leave your foot on the brake and cycle the switch.

Getting back to the step-down gear, it is sensitive not only to the speed at which you are traveling but also the throttle position. And, there is a software element involved the makes the operation of the step-down seamless.

Normally, when you step-down a gear, the throttle position sensor (TPS) tells the engine control module the position of the throttle. If it is within the range that the ECM (engine control module) coniders allowable for step down, then the ECM looks for other telltales. Those telltales include the MAF (mass airflow sensor) and MAP (the Mass Atmospheric Pressure) sensor, as well as the timing sensor and sensors at each wheel. The primary determinant in whether the step-down occurs are the MAF, TPS and timing sensors. If all of these sensors agree that a step-down to the next gear and an increase in torque is warranted, then the vehicle drops a gear and speeds up.

Now, what I think is happening in your vehicle is that one or more of your sensors is out of alignment with the others. Quite likely, it’s the MAF or MAP or a combination of both, plus the TPS that are out of alignment. In your case, they are giving the ECM incorrect information. If you have to let off the accelerator to allow a reset, then it is likely your software either needs an update or maybe it should be a combined with a sensor update to ensure that this problem is solved.

The sensor swap should cost about $300 or so while the software update could cost about $250, so it is shouldn’t cost very much go update and fix this problem.

HostgatorMemberSince you are saying this is a temperature-related issue — it would also certainly seem to be because it only happens on longer trips where the tranny remains relatively cool I’d like to suggest that you have the transmission cooler lines and transmission cooler itself also looked at. You see, the transmission, as I am sure you know, runs super-hot. That heat is not only needed to keep the unit’s internal pressure correct, but it is also needed to set up a natural fluid movement throughout the unit. There’s only so much movement that can be created by the torque converter. Much of the movement through the transmission is controlled by heat differentials. (Cooler fluid settles into areas of the transmission where it displaces much hotter fluid that has moved out of the way. The temperature differential is important for proper operation.)

Looking at how the transmission basically controls its temperatures, you find there are two ways. The first is the transmission case which acts much like the radiators in your home. The transmission jacket radiates the heat that is generated by the internals of the tranny. That heat is then transferred to the transmission fluid. In turn, the fluid’s contact with the case allows the heat within the fluid to transfer through the case to the atmosphere.

Working with the transmission case, the transmission radiator core takes the heated transmission fluid and pushes it through the many galleries in the tranny radiator core. That helps to also take the heat out of the transmission. A third way that also works with the tranny radiator core are the tranny cooling lines. They also take heated transmission fluid and push it through the radiator core to keep things cool.

Given all of this dependence on heat removal for proper operation all it takes is a crimp in a radiator return line or a piece of debris blocking a cooling gallery for first gear and you can have a transmission that acts in the manner you describe.

Here’s what you will have to have done to find the exact location of the problem. First, have your technician look at the transmission radiator core and its support radiator lines. Look carefully at the end of each line to ensure that there is no crimping that might impede coolant flow. If everything looks good here, you’ll have to have the transmission pulled out, properly drained and then taken down to the gallery level so that you can see if there are any blocked galleries. This is time-consuming work and requires your technician to run each gallery with a long, thin, snake-like device. This will not only clean each gallery but it will also find whatever might be causing the blockage. This level of cleaning and work may cost the better part of $4,000 because it is so labor intensive.

Here’s one alternative I usually don’t mention when dealing with transmission and that is a high-pressure flush. If you have had your transmission taken down to this level, then it makes sense to clean out all the galleries. Because you have removed things like the torque converter and other devices that are easily damaged by deposits or items like large metal filings and such, then it makes it easier to do the high-pressure flush to blow out any obstructions.

Again, this is not inexpensive as it will cost the better part of $3,000 for all of the work. But, if you want to keep the 1999 on the road, then it is worth the effort.

Good luck, let me know what happens.

HostgatorMemberWith all of the electronics in today’s cars — even 1990 models — it’s a wonder that they sometimes run at all. Back in 1990, your Lexus likely had a minimum of six individual microcomputer systems controlling various things. For example, your emissions system had a computer controlling things and your transmission also had its own microcontroller. Likewise, the ignition system had a computer as did your Lexus’ safety systems (brakes, ABS, airbags). And, then there was the early infotainment computer that also controlled the NAV system (if it had one installed). And, of course, there was the microcontroller that took care of the air conditioning and heating. Each system reported to the engine management computer.

The difference between the computer systems of that era and today is the degree of connectivity. Today, each computer system “talks” to and is “heard” by all the other underhood computer systems. Ultimately, they all report to the engine management module, which is always listening via the CAN (Can Area Network). The engine management module is a far more powerful processor than anything imagined in 1990.

With that said, given the number of individual computer-managed systems under the hood of your Lexus, it is quite possible that though problems look as if they are being generated by the transmission system, they aren’t really. You see, 1990-era cars many times multiplexed their signals so that the individual computer-controlled systems could share the data generated by individual sensors. This meant that where a sensor today usually only has a set of networked wires, the sensors back then had multiple looms of wires and connectors that could come apart and short out or go open.

When a short or open in a 1990-era vehicle occurred, its actions were just as you described. I suspect that what is happening is that you have looms of ancient wire that have become brittle and are losing good contact with the networks they are supposed to be talking to. Instead, various wires may be coming a bit loose and are touching so that one moment your dash your headlights may go out while your transmission is working. At another moment, you will find that your reverse gear is not working — as you have said is happening — while at another time, you may find first and third are not working.

Since this is honestly an electro-mechanical problem and only slightly related to your transmissions — though it can seem like it’s all a transmission problem because of the number of times the transmission has failed — you need a good general mechanic who has certifications in not only electrical work, but also electronics work. If you find a NIASE (National Institute for Auto Service Excellence) with the proper credentials, drop your car off there for an estimate. I am willing to bet that at the end of the day you will find this cost is very prohibitive. You may have to have the entire vehicle rewired which is very time-consuming. It can take more than a day of working time ($144 hourly times 8 hours) to do just one circuit. If your car has several circuits that have to be rewired you are looking at $1,152 per day times four or five days or more. If you have that type of money laying around, then go for it, but keep the 1990 as an antique and find a new daily driver, which is raising your cost even more.

Ultimately, I have to tell you that it makes more sense to take the 1990 off the road and have it worked on as you can afford it because you are looking at a minimum of over $4,000 just for some wiring. It could easily cost much more than that. Obtaining a new daily driver where you only have a relatively small monthly payment is the best way to go, in my opinion.

April 30, 2017 at 7:10 pm in reply to: Transmission Disengages for a Second Over Rough Surfaces #9543HostgatorMemberThis sounds like an electronic problem and if I had to guess it’s location, I’d say it is in the solenoid packs on the transmission.

The reason I am making this judgment is simple: On nice, smooth road surfaces, everything is fine. However, when things start to go snap, crackle and pop on rough roads, the solenoids may jiggle around and may momentarily lose contact with the other side of the circuit. The result is that the transmission disengages and re-engages. Further, it is also possible that the connective wiring has loosened up from its terminals and the result can be the same.

Fortunately, this is a relatively easy fix. It should cost you about $175 per unit including labor. This fix is replacing each solenoid and its wiring. Since there are usually two physical units (each duplexed — one unit housing two units), the whole cost should be around $350 to $425 max.

Once you gave this fixed, your BMW will be set to go.

One last note, you mentioned this happened when your transmission warmed up. Honestly, what I believe is happening is that your engine and transmission are heating up the solenoid packs and wiring to the point where the wiring may just be coming a bit loose which is also contributing to the problem. Let me know how it turns out.

HostgatorMemberI am afraid your Escort is one sick puppy. My thinking about this is simple, your transmission shop would not have seen pieces of metal in the pan if there wasn’t a problem to begin with.

It is nice to think that it might be a CV joint or piece of a half-shaft that is causing the problem because you are likely thinking it means that the tranny won’t have to be replaced with the $4,000 bill that you are likely facing (the Escort uses a front transaxle because it is front-drive which makes things more expensive) if the problem turns out to be the transmission and not another device.

It is impossible for pieces of a CV joint or half-shaft to be pushed into the transmission because the transmission is effectlely a sealed unit that has to be taken apart to be worked on. Now, it is possible that the CV joints are shot and the half-shaft may be bad as well, but that is a mechanical issue unrelated to the transmission.

So, here’s my thinking tell your transmission shop to order and install a rebuilt tranny because it is the only thing that will solve your Escort’s problem. Let me know what happens.

HostgatorMemberBefore you panic, I would have everything looked at again and retightened according to spec. You indicated that all of the screws seems to be backing out and that the transmission seemed to be put back together poorly.

With that said, take your Sentra back to your dealer and have one of his transmission specialists tighten each part of the transmission to spec with a torque wrench, not with an airgun.

Many times when technicians are in a hurry to get a job done so they can move on to another job, making a double fee if they are quick enough, they will use an airgun and wrench to torque things down. This automatically means the device is over torqued. An over-torqued transmission is going to perform poorly simply because it is too tight and parts that are supposed to be in one position — and would be if they were properly tightened to tolerance — are out of position. This means that you might end up with a skewed transmission.

Now I know that the dealer’s technician will likely complain because using a hand torque wrench and looking for the proper tolerances takes extra time. In the long run, I think it is worth it.

One other thing to have rechecked is the pressure plate assembly. That assembly is made up of not only the pressure plate but also the throw-out bearing as well as the friction plate and the flywheel facing. (When you press the clutch in, the throw-out bearing separates the pressure and friction plates so that you can shift your car without having the engine and drivetrain connected.

I am willing to bet you that your technician will find something improper about the repairs that were made. This could cost you as much as $800 — yes it is expensive — but it beats spending $2,750 for a new transmission and parts, doesn’t it?

-

AuthorPosts

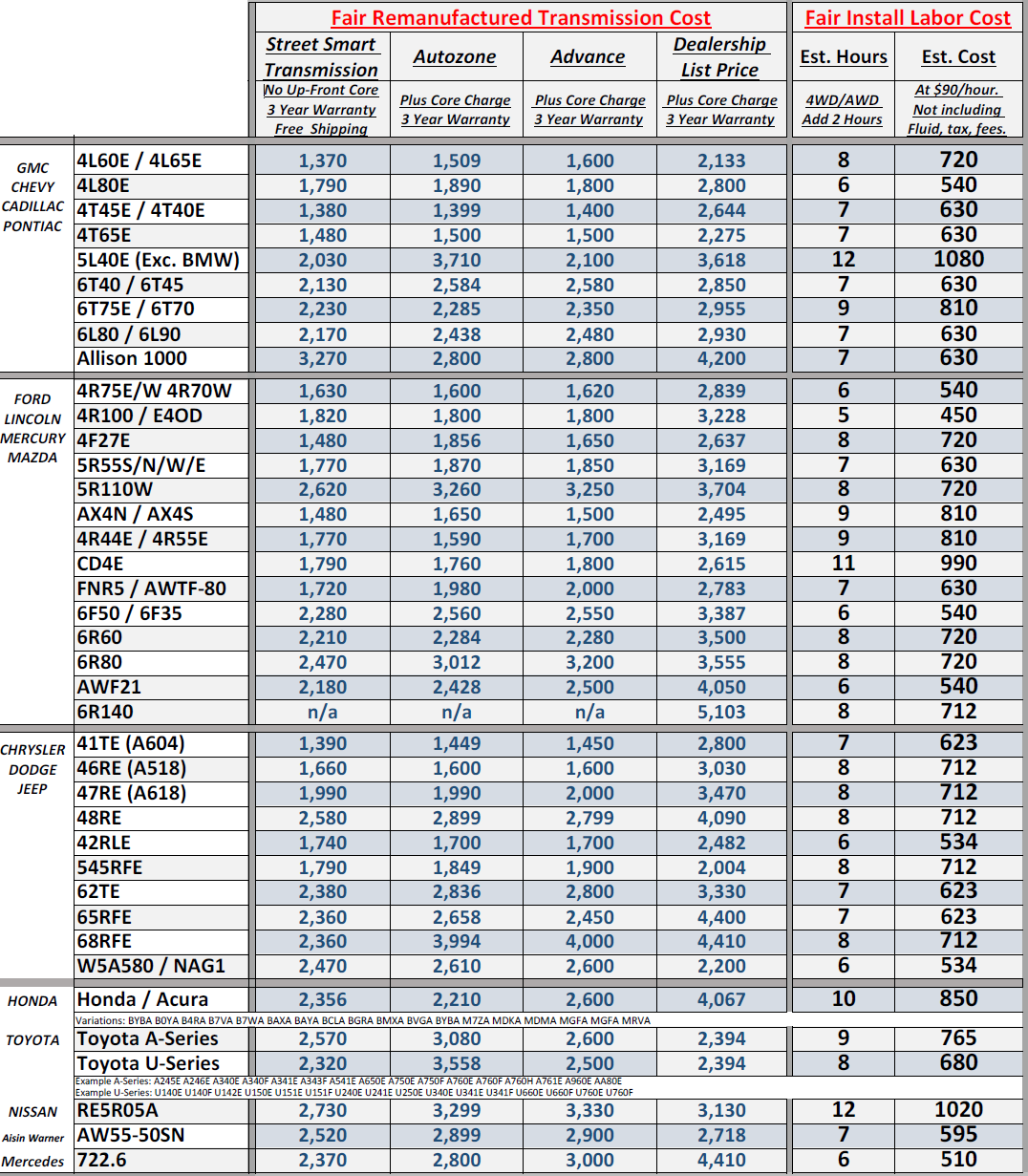

Fair Replacement Transmission Cost by Vehicle

- Use the Year / Make / Model lookup tool to determine what transmission your vehicle has. [transtar]

- Find your transmission model in the table below for fair prices from reputable suppliers. Also fair labor cost for local installation at a local auto repair shop.

- Get a free estimate on a remanufactured transmission by email.

Fair Remanufactured Transmission Price Ranges by Transmission Model Updated May 1, 2018