Forum Replies Created

-

AuthorPosts

-

HostgatorMember

It sounds to me as if you have the beginning of a problem with the clutches/bands. What is happening is that they are trying to engage, but failing and slipping, giving you the jerky feeling. There are likely two causes of this, either the devices themselves are failing — always a possibility — or there just isn’t enough fluid in the transmission to make everything work right.

You didn’t tell me how much fluid was in the transmission, so I would suggest checking the fluid level at your next opportunity. It’s easy to do. In fact, we have a section in our comments area where we tell you how to do it. Here’s a link that describes how to check and change the fluid .

I would be willing to be you will find that your fluid is down a bit. If it is, pickup a can of the proper replacement fluid (you can find it in your owner’s manual) and then slowly add it in, making sure you check the fluid reguarly to ensure you don’t overfill. That should take care of it. Let me know if this helps. I think it will.

Need a replacement transmission? Quality transmissions are hard to find. Free estimate to your email.HostgatorMemberThanks for your confidence, I hope you still think it’s justified when I tell you that for all the time you have waited, you could have installed the rebuilt transmission your Nissan needed and you could have had the use of your car.

There are several scenarios that could have produced the various sounds you heard when your Nissan stopped moving. I suspect that what happened was quite simple: there was a problem on the input shaft that translated over to the torque converter and initial gearing. Then, as the torque converter started to spin up, something bound — possible a gear — and that accounted for the loud snapping sound you heard.

It is possible, of course, that everything worked as it was supposed to until it hit the planetary gearing where the ultimate gearing choices are made, depending on the action of the valve body and/or the solenoids.

With all of that said, though, the bottom line is that it is quite likely that one or more of your tranny’s major systems are shot and the result is that you need a rebuilt installed (when I talk about a rebuilt, I am also saying “new” or “replacement.” Because of the size and complexity of transmissions, it makes little sense to try to replace each transmission subsystem, unless it is one of the solenoid packs or, perhaps, a valve body problem. In those case, the cost of repair parts and labor is low enough — $150 to $500 — so that it makes sense to repair the individual systems. Going beyond into the multithreaded systems the interact and need subsystems, each subsystem can caost upwards of $1,520 to replace and so when you finish replacing one and then, possibly, another, you will find the cost skyrocketing.) To keep costs as reasonable as possible, install the rebuilt transmission for $3,200 and you will be better off. Let me know what you decide and what happens next.

HostgatorMemberThere are several potential problems with our Jimmy’s transmission, none of them is unsolvable and they aren’t terribly expensive, either.

First, even though the transmission fluid color looks okay, your fluid might be down slightly. If this is the case, then the tranny will be working overtime to add enough pressure to the existing fluid in order to enable that all parts work properly. This, however, does leave some parts exposed at times and can lead to slipping which is the type of problem you are talking about. Check to see fluid level is okay. If it isn’t, then add enough fluid, very slowly to assure you aren’t overfilling the case. A little too much is the same as down just a bit, so be careful.

As to the other problems. It is quite possible there is a plugged gallery in the valve body which is preventing the fluid from flowing correctly and accessing the proper gear. All it takes is a faulty check valve (a spring-driven, light ball bearing style valve) to prevent it.

It is also possible that the gear solenoid actuators are also causing problems. Since these devices are pretty accessible, it is easy to have them checked.

Whatever way you are looking at it, I don’t think there is much a problem with the pricey stuff in the transmission, the torque converter, input-side gearing, output-side gearing, clutches or bands. Instead, you will likely find the problem in the areas we have discussed. The good news for you is that you are looking at a likely maximum cost of about $750 for the works.

I hope this helps you out. Let me know what you find.

HostgatorMemberAh, then it sounds like the cable within the runner in the gearshift cable has stretched and the cable is binding. It is the way the cable is made. Normally, what happens when you shift is that the cable has stretched and instead of taking up any slack, causing the shifter to hunt for the proper transmission setting point.

If everything is working as it is supposed to within the runner, the cable works against its anchor point, usually installed in the valve body. The anchor point can consist of a bar that makes the actual selection in response to the cable. Once your vehicle has found its shifting point, the vehicle’s transmission responds by selecting the proper path in the valve body so that the proper gear is chosen. Once the proper great kicks in, life is good. However, sometimes, until you find the right gear, things can be weird.

HostgatorMemberIt sounds like you are actually having a problem with the keylock cylinder, rather than the gearshift. Normally, when you shift into Park, you place your foot on the brake and the neutral/start switch disengages and de-energizes the ignition circuit. If the keylock cylinder doesn’t go all the way home, you will not be able to place your car into Park.

By the same token, you will not be able to remove the key from the ignition, either.

You also said that when you wiggle the gearshift the dash light flickers and there is a clicking sound from the dash. What is happening here is the keylock circuitry is partially energizing. Again, this indicates that the problem, like as not, is in the keylock cylinder.

March 16, 2016 at 7:10 am in reply to: Ford Transit Gears Not Shifting – Gear Activator Solenoids #4171HostgatorMemberFrom the sound of it, there are likely two problems affecting your Transit. The first is a binding gearshift cable and the second appears to be with the gear activator solenoids.

Here’s what happens when you normally shift your van. Let’s say you select drive and slide the gearshift selector to the D position. There are a couple of issues that should happen here. As you pull the vehicle out of Park, the dog collar securing the output shaft releases and allows the transmission to work correctly. Once the dog collar is freed up and parked for normal operation, the torque converter spins up and starts transmission fluid flowing threw the transmission. At this point, depending on the input from several sensors, your transmission chooses the gear it wants to start off in. In a five-speed, it means your Transmit may start off in first to fifth.

The actual choice of gearing is governed by the solenoid. There are usually two solenoids located on the valve body, one internal and the other external (some multi-geared transmissions may add another). Depending on which relays are set to fire by the solenoids, you then have the final gearing choice that is sent along to the clutch/band combinations.

In theory, it is quite easy to do. The reality is far different as the solenoids must fire at the right time; the valve body has to be clear and free of debris so the proper check valves allow the right gearing choices and fluid route. Now, if one of the solenoids fails to fire for one reason or another, not only will your Transit shift in the manner you describe, but it will also likely go into limp-home mode, which you also touch on in your question.

If your transmission goes into, say, first and reverse and no other gears, your transmission is in limp-home mode because the engine control computer (ECC or ECM) has received a code from a sensor or other electronic device telling the ECC there’s a problem.

So, now we have all of the possibilities on the table. The good part, for at least two of them — the binding cable and solenoids — is that they are relatively quick and inexpensive to fix. If you have to repair the transmission select cable (a gearshift cable within a runner) because it has stretched beyond all belief due to years of wear), as well as the solenoids, you are looking at a parts cost of about $450 and labor of another $300. This is far better than installing a rebuilt transmission for $3,400, isn’t it.

If, on the other hand, the problem is more serious — an error code and limp-home mode — seem to indicate that it might be, then you are looking at the diagnostic and locating the problem. I suspect that your ultimate problem (number four) is, like as not, in the planetary gearing itself. The only way you are going to find this out is a major diagnostic teardown which will cost on the order of $1,450, plus any replacement parts. In this instance — only this one — I’d suggest a rebuilt transmission because your ultimate costs will be less. Please let me know how this works out.

HostgatorMemberThat your Impala is a “salvage” isn’t germane to the question. The important thing is that what your Impala is doing. Let me see if I have this right: the tranny is buzzing a bit on gentle starts and later on it feels as if there a clunking and mild sticking before full engagement.

That said, it definitely sounds to yours truly that one of the two shift solenoids may be sticking somewhat. Normally, the shift solenoid or combination will just work smoothly and you won’t notice anything. When a solenoid gets sticky, it acts much like you describe so I would suggest you start there.

Bring your car into a good shop and ask the tech to do two things, one, give your vehicle a test drive and two, ask him to run a diagnostic check with and OBD-II scanner to see if the engine control module has caught any codes that could determine whether there is a serious problem.

That said, I would suggest having all of the solenoids swapped out. It is a job that, with labor, should top out at $600 for parts and labor. More likely the cost will be $450 to $500.

One area to have checked, just to make sure there are no further problems lurking in the wings, is the clutch/band combination. If the clutches are beginning to slip then your Impala’s operation may match those symptoms as well.

Please let me know what happens as I am interested in hearing.

March 9, 2016 at 6:05 am in reply to: 2008 lincoln mkx: TSS/OSS sensors vs. transmission rebuild #3992HostgatorMemberThe TSS/OSS service bulletin is what you should “listen” to and not someone trying to build business with $3,000 tranny rebuilds. Quite frankly, the sensor issue is quite well known and it is the first one I would have suggested when you indicated the error code.

It’s interesting that one of the mechanics noted he could find no codes when he scanned the system. I believe I know why. When you had the system scanned the first time and the 0722 code popped out, I believe the technician reset the engine control module (ECM) so that all error codes are cleared. Sometimes, if codes aren’t cleared, your vehicle can indicate there are problems when, in fact, everything has been cleaned up.

That’s why, I think, the tech did a reset to make sure that once any work was done (I am sure he was presuming there would be some substantive transmission work heading into one of the bays where he could make a few extra dollars) your vehicle would operate correctly and not throw false codes.

At least you can say the first tech did have a conscience.

My ultimate suggestion is go to a third shop — ask around work, if you don’t know of any shops, other than the first two, and have the sensors installed. I think you’ll find your Lincoln is going to feel a whole lot better and that it will operate quite nicely, as well.

Could you do me one favor? Please let me know the outcome. I do like to hear what happens.

HostgatorMemberWith 186K on the transmission, I have to say that the borrowed time your BMW was living on has been cashed in and run out. Frankly, it could be any number of things, but, the most likely culprits are the torque converter and/or the clutches and bands. Either way, the result is a Bimmer that will start and sounds great, until you try to drive.

There’s really only one thing that I can recommend for your BMW and that’s a rebuilt transmission. It is the most reliable way to handle things, and the least expensive, too.

Yes, it is possible to start diagnosing things and replacing one system after another in the transmission in the hope that either a. you can get going again or b. you can keep costs down, but — and here’s the thing — I don’t think either will happen. What will happen is that you may make a bit of process toward getting things solve, but, when you have the transmission put back in its case and you fire up your Bimmer, you’ll still have problems. And, the not-so-funny thing is that as you replace one system at a time, your costs will jump so that by the time you are finished (presuming you replace everything one system at a time) you are probably going to have paid out about $12,000 or so.

It is much better to invest the $3,400 or so that you will have to put into have a rebuilt transmission installed in the BMW and call it a day. You should be alright for lots of future miles.

Please keep me in the loop on this, I like to hear the outcomes.

HostgatorMemberHow long is a bit? Just depends on the timing. If it is a second or two I wouldn’t worry about it. Just my experience.

HostgatorMemberSounds like a transmission problem and repairing that could cost anywhere from $1000 to $3000.

HostgatorMemberIn a traditional manual transmission, everything is pretty much in line — engine, transmission, differential. When you shift, depending on the position of the gearshift, you are choosing one of three rods that, in turn, chooses a different fork for a different gear. As you move through the gears, different combinations of rods and forks move as you go through the gearshift pattern and put the right gears in contact with the layshaft at the right times.

The steps that make this occur are:

* Press clutch in

* Shift gears

* Release clutchThe Mini, like most front-drive subcompacts, differs to a major degree because of its engine placement. Instead of being mounted North to South where north is the front of the car and sount is the rear, the engine is mounted East to West. This introduces another level of complexity into transmission work.

In the traditional engine/transmission layout, the general direction of movement is back and forth. In a transversely mounted layout — the type used in your Mini — the movement is side to side. Yet, when sit in your Mini you are still oriented North to South (you look at the front end and the rear end is behind you) and all of the actions are similar.

This is where the complications set it, just because the combined engine, transmission and axle (transaxle) are at adds. To smooth things out, the Mini uses a set of cables to shift. A known problem on these cables. There are two cables that use spherical end joints whose rubber can wear. When these cables wear, your Mini will exhibit the problems you discuss. It’s simply because the either bind up or fail to function that you lose your shift.

The good news is that you won’t have to invest 1,000 pounds to replace the transmission. You will likely have to spend about 250 pounds and it is will be a fairly quick repair, maybe four or six hours.

February 26, 2016 at 6:13 pm in reply to: 2003 DeVille – How Many Hours Does it Take to Replace a Transmission? #3944HostgatorMemberYou’re right about the shortcuts. When you have been in the transmission repair business for a bit, like any other business, you develop workarounds to facilitate getting the transmission in and out of its housing. Factory manuals are written to guide first-time or inexperienced technicians through each step of a routine and they are expected to follow it number by number. The same is true of advanced do-it-yourselfers — provided you have the specialized tools and support equipment that you have. As you have learned, each step builds in extra steps to ensure that each portion of the removal or install process is down correctly. Over time, if you did this every day, you would find that you’d develop your own set of workarounds.

For instance, let’s say you wanted to remove the exhaust system clamps or brackets, what would you do? Most people would likely try to put a socket on a nut and then move it without trying anything beforehand. However, you would speed things up by simply starting up your car or truck and letting the exhaust system warm so the fasteners were also warmed. The warmed fasteners will spin off rather quickly. Cold fasteners tend to stay firmly bound to their mounting surfaces, while heated fasteners expand a bit and loosen. Even before warming, if you wanted to speed things further, you could hit them with WD-40 or another penetrating oil and then warm things up. You will find things work quickly this way.

If you hadn’t been involved in transmission work and hadn’t done steps like this before, your frustration levels would be quite high as you would likely not only strip fasteners, but you might also shear them off, leaving you with further problems if you break a clamp or bolt off without loosening it so that you have drill out and then tap and die the mounting point. That’s the problem with cold nuts, bolts and other fasteners.

And, this is only one quick example. And, yes, it’s a lot of words to say you are right.

By the way, you are right! Now that you’ve pulled and replaced the tranny twice, your job will likely go much more quickly. It’s just a matter of doing the work and finding the quick steps.

February 26, 2016 at 2:06 am in reply to: 2003 DeVille – How Many Hours Does it Take to Replace a Transmission? #3932HostgatorMemberThanks mstern001. Unfortunately, it’s the second time I had to replace it and it looks like it will be a third. Sometimes it doesn’t pay to over-maintain.

The first time, it took my son and I the same 4 days. However, we replaced the PS pump, hoses, and, steering rack the first time too…since we were in there anyway… Again, the second time I was working alone.

Another thing that ate time, is that we followed the Factory Service Manual to the letter. I’m guessing that a trans shop would probably skip a few of these steps. For instance, the book says the trans can be tilted in order to clear the starter snout. we couldn’t figure a way to make that happen, even with the brake lines and left trans mount out of the way. So I removed the upper intake and starter.

I’m thinking it will take even less this time around. I learned a valuable lesson about where NOT to buy a rebuilt transmission. Next time it will be a factory authorized reman.

February 25, 2016 at 4:59 pm in reply to: 2003 DeVille – How Many Hours Does it Take to Replace a Transmission? #3929HostgatorMemberMost transmission shops will probably charge you about 8 hours labor to pull the tranny from your deVille, quite a difference from your experience. That said, remember they are specialists in transmission work and what one of those techs can do in a day is amazing, especially to a non-specialist.

HostgatorMemberIt sounds like your tranny is in limp-home mode because of its problem or problems and won’t shift out to normal operation. That’s as much as I can say, right now, because I need more information. You said that three fault codes were generated (something in the XX7X range, like as not). If you could let me know what they are, I can then put on the patented thinking cap and help you out.

Let me know when you have a minute as I think I may know the answer, but it really does depend on the error code that the ECM (Engine Control Module) picked up from the Transmission Control Module (TCM).

February 25, 2016 at 4:34 pm in reply to: 1997 VW Cabrio $900 Labor to Replace Used Transmission #3927HostgatorMemberTo answer your question about the clutch first. With what you are telling me about the condition of the transmission, I suspect that they will keep things the same on the clutch side of things. That is, your clutch, throwout bearing, actuators and the clutch plate are likely to stay the same, since they seem to be trying to keep things as cost-effective as possible for you (you did say they were repairing your old transmission to keep your car rolling until they found a replacement, right). That said, I think most of the pieces of your clutch will be okay.

Now, as to your main question. You are actually working with two different issues here. The first is the older or used transmission for which they found a part that was used to keep your Cabrio rolling. Indeed, $1,475 to replace the part is relatively reasonable given the possible costs you are facing with any transmission.

The $900 labor charge is for the replacement transmission, the second issue here. The total cost is about $2,375 or the replacement cost for a multi-speed manual (I think your Cabrio had a five-speed, if memory serves me correctly). Now, here’s the interesting thing. You didn’t indicate there would be any more than a $900 cost for the replacement tranny, so I believe that they are giving you a credit for the device itself. They can’t discount the labor, though, as the shop does have to make a bit of money to enable it to pay things like bills.

And, no I don’t think the labor charge for the replacement transmission is too high. If anything, it is lower than some costs I have seen lately.

HostgatorMemberIt may seem like a strange diagnosis, but, I suspect that the parking pawl — the ringed gear that engages engages when you put your car into Park and keeps it from rolling — may have slipped and engaged. It is very likely that the solenoid that engages the pawl misfired, probably due to an electrical fault, and engaged. That would account for the strange noise and the lack of movement since. If it were a gear then it is likely you would still be able to push your VW forward, though with a lot of help (you have a lot of transmission fluid and transaxle working against you). If it were the torque converter, again, you would be able to push your VW forward, again with lots of effort.

I wish it were as simple as just the fluid levels — your VW would either be in a limp-home mode or it would still roll, albeit with difficulty — or even a solenoid or valve body, but it is not. When the pawl engages and locks things up abruptly there’s sure to be damage to the output shaft, maybe the gears, like as not the clutches and bands and, even, the input shaft. It really tears up the tranny.

Your only choice here is a rebuilt transmission for about $3,400. You have to hope that there’s no damage to the half-shaft from the wheel. Please keep me in the loop on this.

February 24, 2016 at 1:49 pm in reply to: 4 Wheel Drive Doesn’t Work After Replacing Transmission #3867HostgatorMemberUnfortunately, it’s a chicken-egg think, which came first? It’s tough to know which went when, but, suffice it to say that you know the problem now and it’s on the way to being fixed. Yes, the price is steep, but, once the second issue is fixed, you are good to go for a long while.

Good luck.

February 23, 2016 at 1:42 pm in reply to: 2001 Pathfinder 4×4 Automatic Whirring in Park and Neutral #3845HostgatorMemberThe problem is fairly simple to define: it is more than likely the torque converter. Indeed, just “earballing” the problem (you can’t really eyeball a transmission problem so you have to rely on what you hear), tells me that the torque converter is failing. More specifically, the problem more than likely lies with the turbine input blades that take the output of the converter, increase the pressure and then shunt the output throughout the transmission housing.

From the sound of the problem, the torque converter itself is working correctly, but, the turbine is taking longer to spin up and work correctly. It is something you have to expect at the mileage you have on the Pathfinder. And, while I am a fan of the Pathfinder — I enjoyed driving them when I worked at several local dealerships a few years ago — even as tough as it is, parts begin to fail at high mileage.

Since the turbine is likely the key piece of the torque converter that is going, it must be replaced. Here’s the irony of the problem. The turbine and its vanes cost about $600 or about $950 (AUD). for the basic parts. The need to completely empty the housing and then tear down the case and pull out the transmission so you can replace the turbine will cost you another $1,400 (USD) or about $1,800 (AUD).

Here’s an idea to consider: think about replacing the transmission with a rebuilt unit. The reason I suggest this, frankly, is that if you are planning to keep the Pathfinder for a longer time, which I suspect is your aim, then it makes sense to replace the entire unit at once, instead of doing piecemeal repairs that, in the long run, will cost much more money.

As I noted, it will cost about $2,750 (AUD) to replace the turbine and its parts. If, the front part of the converter fails as it may you are looking at roughly the same replacement cost. Just those parts alone are more than $5,500 (AUD). When you add in all of the other costs, piece-by-piece replacement of the transmission will soon outpace the cost of the rebuilt transmission. The fact is that you may end up spending five, six or as much as 10 times the cost of the rebuilt transmission. If, on the other hand, you choose the rebuilt, you are actually saving money.

Please keep me in the loop on this as I am interested to see what happens.

February 23, 2016 at 1:19 pm in reply to: 4 Wheel Drive Doesn’t Work After Replacing Transmission #3842HostgatorMemberThe tranny shop was right, it is not related to your Tacoma’s automatic transmission. The problem is in the differential. Toyota’s system, automatic differential disconnection (ADD), automatically disconnects the front drive shaft from the differential, sliding a sleeve over the end of the shaft. This effectively disconnects the front wheels from the four-wheel-drive system, leaving the truck in rear-wheel-drive only.

The ADD is activated by a system of solenoids and air switches. The solenoids fire the air switches that, in turn, move the sleeve either forward to disengage or back to engage.

What I has happened is that when they transmission shop did the work a vacuum line or a wiring harness was jarred lose or broken. If the problem is wiring then the solenoid will not fire. If the problem is in a vacuum line, the device will not activate. Either way, the four-wheel-drive system fried.

Here are some troubleshooting tips to pass along if your transmission tech isn’t a Toyota repair technician.

1. Check all vacuum lines for the condition of the hoses; their connection points

and alignment — the hoses are color-coded and must line up correctly for proper

operation.2. Check the solenoids. Your technician must ground the hot wire to complete the circuit and

cause it to fire so the solenoid fires. If the solenoid doesn’t fire, the air switch

won’t engage and the four-by-four capability won’t engage.3. Check the sleeves and any associated gearing to ensure they work smoothly.

Please let me know what happens.

HostgatorMemberBy all means, check out the transmission fluid level as soon as you can because that is likely the problem you are having. Or, at least, from a first viewing of your problem that’s what is going on.

The clues that tell me this is likely the problem are really simple to see. There’s a slight lag when going into reverse; drive is taking a longer time to lock up, and you lost reverse once.

What is happening is simply this: Because the fluid level is down a bit, the transmission has to work harder to bring the fluid up to pressure that is needed now to make the transmission work properly. Normally, the transmission fluid doesn’t have to have the pressure increased because it bathes every device within the transmission housing. Howeve, if the fluid drops a bit, the tranny tries to compensate and the internal pressure increases as a matter of course.

At times, when the pressure isn’t high enough, some gears or the vanes on the torque converter turbine are left high-and-dry and the transmission won’t work. At other times, such as on a hard corner, your devices can actually have the tranny fluid peeled away to cause problems.

So, check the tranny fluid level and be sure to see whether your Subaru is down just a bit — which I suspect it is — or whether it is a larger amount. Then, add the proper transmission fluid (check your owner’s manual for the proper type) until it reaches “FULL” on the dipstick.

HostgatorMemberYou’ve heard of good news/bad news questions and answers, right? Well, how about a good news/better news question and answer? That’s the kind of question that you have presented me.

First, the good news: You won’t have to lay out a huge chunk of change for a rebuilt transmission. The reason is that, though, your Civic is ailing, it isn’t the kind of ailment that will cost a huge sum. And this leads to the better news part of the answer: Though you will have to lay out some money, it won’t be all that much, as compared to the rebuilt tranny.

Since the late 1960s, carmakers have used more and more computerization to control cars. At first, the auto industry employed specialized microcomputers that, though they thought digitally, were actually known as analog devices. The devices were assembled into systems that worked on two levels to achieve a result. These devices were the best that the industry could device, at that moment. The industry plainly needed more because these systems were just not capable of the finely threaded control needed to accomplish everything that was mandated by the government.

Fortunately, a development occurred in the mid-1970s that enabled the auto industry to apply tighter control, large scale integration. Large scale integration, and its successor very large scale integration paved the way for tiny computer chips that could be used to control the systems needed to meet the tightening emissions and mileage standards that came out of the Environmental Protection Agency and the National Highway Traffic Safety Administration. At this time, the environmental agency took the lead because Washington was tightening mileage standards and fuel economy standards at the same time. Both goals were intertwined because higher mileage usually meant poor performance, while poor performance meant increase emissions.

The microcomputer and the sensors that it enabled and drove was to prove the key device that enable the car industry to move forward and meet the tougher standards laid on the environment.

Likewise, as safety requirements tightened the microcomputer has enabled the automakers to implement things like anti-lock braking and other things.

With that said — and moving to today — cars now have anywhere between 15 and 27 microcomputer modules or units in the engine bay. The master control unit is the engine control module (ECM). It listens to an internal network of devices that controls everything from braking and acceleration to emissions. The many control modules not only monitor their specific systems, but they also listen to the network and report errors to the ECM.

That’s why your test was able to identify the key to your Civic’s issue, the TCM or transmission control module. The TCM polls a variety of devices including the:

–Throttle Position Sensor

–Mass Airflow Sensor

–Mass Air Pressure Sensor

–Throttle Positioning Sensor

–Crankshaft Position Sensor

–Wheel Speed Sensors

–Brake Switch

–Inhibitor Switch

–Torque Converter Turbine Speed SensorEach of these devices reports transmission problems back to the TCU and ECM that can cause the problems you describe.

In this case, though, you know the device or devices that are failing are somewhere on the electronic side of the equation. Most likely, it is the TCU itself so that all you have to have done is have the device swapped out. That swap-out is your money-saver. Normally, a rebuilt tranny will cost between $3,000 and $3,400, depending on your location. The TCU, while it does cost about $425 to replace, is still far less expensive.

The good news here is that once you have replaced the device the chances are good you will have many more miles of driving in you Civic, although it is also possible another device or two could fail in the relatively near future, which is something to bear in mind and to note. And, by the way, your transmission is fine.

Thanks for your question, please let me know what happens.

February 17, 2016 at 3:57 pm in reply to: 1999 dodge 2500 team my rebuilt and now will not go in to gear. #3593HostgatorMemberHave you checked all the linkages? I know you probably have, but I have to ask you. It’s easy to overlook the most obvious parts. If the linkages are bad then there’s no way the transmission is shifting into gear. Make sure, while you are at it, the cable isn’t binding in the runner. This is another easy one to miss. With that said, you might want to go into the transmission and take a look at the very end of the cable. It should terminate in a lever that’s about four-inches-long. It has a hook at the end. The lever turns about a-quarter of the way around and actuates the transmission shifter. Because it is located inside the transmission, it’s another easy part to miss. However, if you miss it, your transmission won’t go into gear and the truck won’t move.

Also, I would urge you to have your son and his teacher go through the transmission step-by-step because it is possible that a clip or spring may be installed in reverse, keeping everything from working.

I’ll be surious to hear what’s wrong, let me know.

HostgatorMemberWell, you’ve started the process, but you have a way to go. When your Tacoma threw the 0770 code it was complaining that there was a problem with another solenoid, the Lockup Converter Solenoid. Normally, the Torque Converter Lockup Clutch maintains a 1-to-1 ratio between the input shaft and the torque converter so there is an effective lock between the transmission and engine. This is similar to the lock you achieve in a manual when you shift into a new gear and let the clutch back out. In reality, the lockup torque converter allows for a slight decrease in engine rpm so that can achieve better mileage while maintaining a speed. It is what is known as the “lockup torque converter” and functions like an overdrive setting.

Because you are seeing the P0770 code, the Powertrain Control Module (powertrain converter) is seeing a difference in the rotational speeds of the torque converter and the input shaft. The P0770 code appears when the difference between the settings is 200 rpm.

There are several possible causes of this problem. First, the torque converter lockup solenoid may be bad. Second, it may be a bad engine coolant temperature sensor. Third, it could be a bad torque converter clutch. Fourth, it could be a defective valve body or the tranny fluid may be dirty and the dirt is restricting its flow.

As to the specific cause of your problem, I would have you check the lockup solenoid. They should do more than just cycle the solenoid. Instead, your technician should monitor the solenoid in action during either a dyno test where the tranny goes through the gears or during a road test with you at the wheel. If that is working, then you will have to have them look at the engine coolant temperature sensor. Finally, I would urge you to have the converter clutch checked as well.

I honestly suspect the problem could be in one of the areas I mentioned. Indeed, I think you should swap out all three, if you can afford it. Make no mistake about it, this isn’t a $150 repair. Given the amount of teardown — the primary reason you do all three fixes at once — your technician will have to do, you are looking at a $1,750 to $2,150 bill. If you swap out all three parts while the transmission is open you will be taking care of the problem, whether it’s only one of the parts mentioned or all three.

-

AuthorPosts

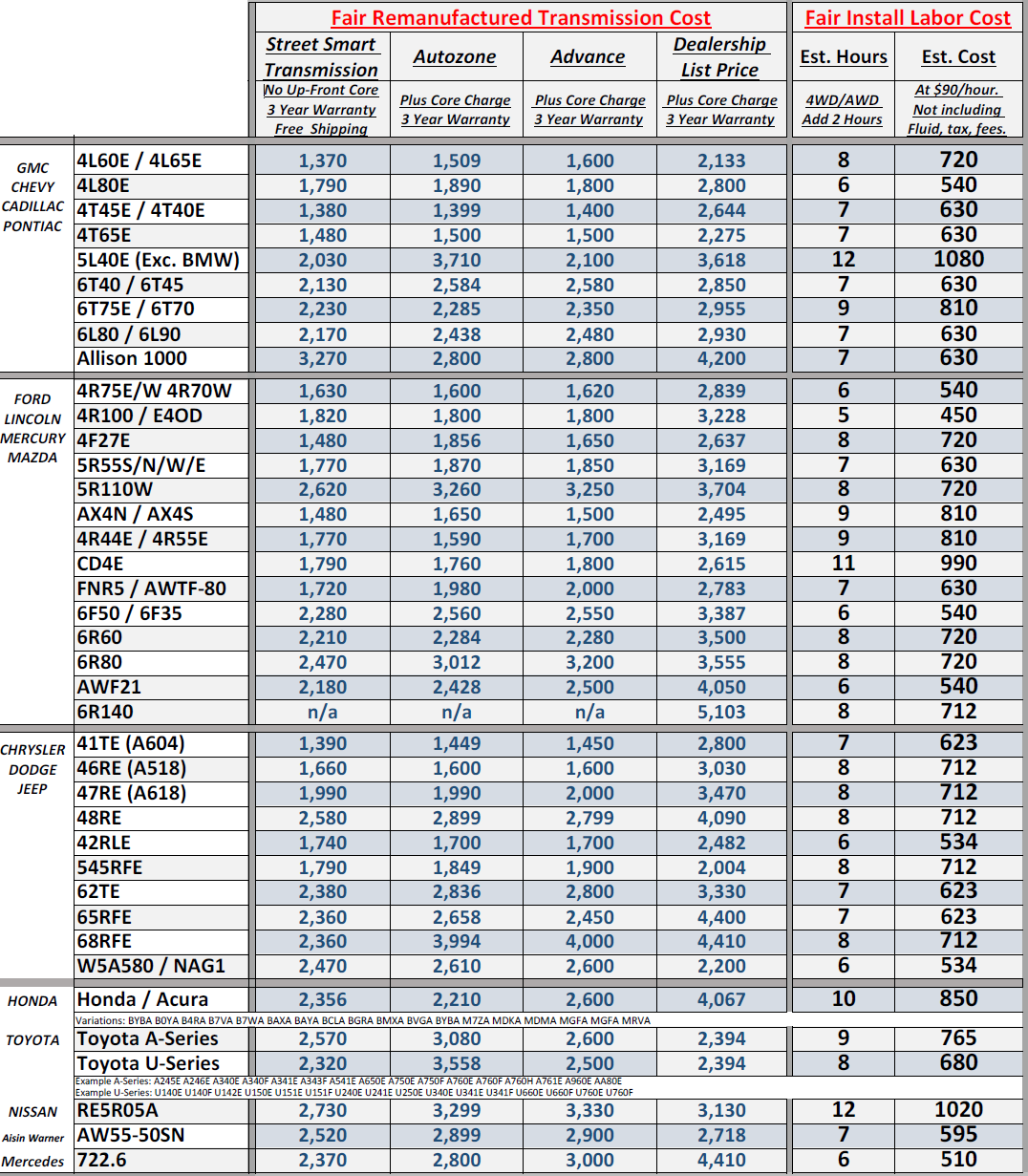

Fair Replacement Transmission Cost by Vehicle

- Use the Year / Make / Model lookup tool to determine what transmission your vehicle has. [transtar]

- Find your transmission model in the table below for fair prices from reputable suppliers. Also fair labor cost for local installation at a local auto repair shop.

- Get a free estimate on a remanufactured transmission by email.

Fair Remanufactured Transmission Price Ranges by Transmission Model Updated May 1, 2018