There are over 1,000 parts inside of the average automatic transmission. Needless to say, that adds a lot of complexity to the manufacturing process. Each individual part has to have a place to go inside of the case, and all of these transmission parts have to be strategically located so they can do their job. To increase manufacturing efficiency and reduce the overall size of the transmission, many automakers have started to combine sensors and solenoids into a single unit called a transmission TEHCM or Mechatronic. These all-in-one units are bolted to the valve body, and the transmission control module/TCM is often integrated into this assembly. A Transmission Electro-Hydraulic Control Module does reduce the complexity of the transmission of design. However, if one of the sensors or solenoids connected to the TEHCM/Mechatronic fails, you have to replace the entire assembly.

What Transmission Do I Have?

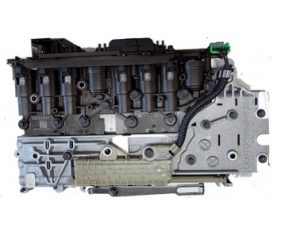

Anatomy of a Transmission TEHCM / Mechatronic

The frame of a typical TEHCM/Mechatronic is made from  molded plastic and has integrated circuitry or wiring so that the various sensors and solenoids can communicate with the TCM and ECU. Most of the time, the transmission control module will be integrated into the TEHCM. So locating the solenoids and sensors only a few inches away from the TCM, allows for faster and more precise electronic control of the gearbox. Now let’s take a look at some of the components that make up the typical TEHCM/Mechatronic.

molded plastic and has integrated circuitry or wiring so that the various sensors and solenoids can communicate with the TCM and ECU. Most of the time, the transmission control module will be integrated into the TEHCM. So locating the solenoids and sensors only a few inches away from the TCM, allows for faster and more precise electronic control of the gearbox. Now let’s take a look at some of the components that make up the typical TEHCM/Mechatronic.

Shift Solenoids – These little plunger devices are designed to allow or restrict the flow of pressurized transmission fluid down different passages inside of the valve body. The fluid pressure in turn, forces various clutch packs to move gears around so that the gear ratio can change up or down. Some of the most common transmission solenoid problems include:

- Slipping

- Harsh shifts

- Delayed gear changes

- Delayed gear engagement

- Failed gear engagement

- Transmission overheating

Pressure Control Solenoids – An automatic transmission operates by using pressurized hydraulic fluid (a.k.a. transmission fluid) to move gears around. The pressure control solenoid allows the TCM to increase or decrease the hydraulic pressure in various circuits to control the different gears and the torque converter. Common pressure control solenoid problems include:

- Slipping

- Harsh shifts

- Delayed gear changes

- Delayed gear engagement

- Failed gear engagement

- Transmission overheating

Transmission Line Pressure Control Solenoid – This plunger device is activated by electrical pulses sent by the TCM. It operates a spool valve inside of the valve body, which raises or lowers the hydraulic pressure inside the transmission, based on a number of factors including engine load and vehicle speed. Common line pressure control solenoid problems include:

- Harsh shifts

- Slipping

- Failed gear engagement

- Limp mode

- Transmission overheating

Transmission Pressure Switch – The pressure switches inside of a TEHCM/mechatronic monitor the fluid pressure created by the transmission pump, then relay the data to the TCM and ECU. This helps the computer to determine the correct gear ratio, current gear ratio, and whether or not there is enough hydraulic pressure to safely operate the transmission. Common transmission pressure switch/line pressure switch problems include:

- Limp mode

- Engine stalling

TCC Pressure Control Solenoid – A torque converter pressure control solenoid controls the amount of hydraulic pressure used to engage and disengage the torque converter clutch. Common TCC solenoid problems include:

- Failed torque converter lockup/lack of overdrive

- Reduced gas mileage

- Engine stalling

- Transmission overheating

- Limp mode

Transmission Fluid Temperature Sensor – Another common sensor that is integrated with many TEHCM/Mechatronic units is the TFT sensor. It monitors the temperature of the transmission fluid and relays the information back to the ECU. If the temperature exceeds safe levels, the transmission will be defaulted into limp mode.

Transmission Input Shaft Speed Sensor – Built into most TEHCM/Mechatronic assemblies is the ISS sensor (turbine speed sensor/TSS), which works in conjunction with the output shaft speed sensor/OSS to tell the computer what gear the transmission is in, based on how much power the sensor detects coming into the transmission from the engine. Common ISS sensor problems include:

- Erratic shifting

- Engine stalling

- Limp mode

- Speedometer failure/fluctuation

- Cruise control will not operate

- Transmission will not shift

Output Shaft Speed Sensor – Another common TEHCM/Mechatronic sensor is the output shaft speed sensor, or OSS. It measures the rotations of the transmission output shaft, which helps the computer to determine if the transmission is in the correct gear. Common output shaft speed sensor problems include:

- Erratic shifting

- Transmission refuses to shift

- Engine misfires/hesitates

- Limp mode

- Speedometer failure/fluctuation

- Cruise control will not operate

Transmission Range Sensor – The transmission range sensor detects what gear you have moved the shifter into, and relays that information to the ECU. Common transmission range sensor problems include:

- Engine will not start

- Engine only starts when the shifter is in the Neutral position

- Erratic transmission shifting

- PRNDL instrument cluster display problems

- Non-working reverse lights

More information about specific TEHCM/Mechatronic assemblies

Ford 6R80 Mechatronic & 6R80 Lead Frame

Solving TEHCM / Mechatronic Problems

Because of their design, it’s not possible to simply replace a failed component like a temperature sensor or speed sensor. Instead, you have to install an entirely new TEHCM/Mechatronic to make sure that all of the components work together properly, and wear at the same rate. There are of course, many aftermarket kits that say they can allow you to replace individual components on the mechatronic / lead frame. But that will only offer a short-term fix, because other components within the mechatronic / TEHCM may be damaged or worn as well.

All TEHCM/Mechatronic assemblies are located inside of the transmission on the valve body. Objectively, it is a fairly simple repair: simply remove the transmission pan, remove the valve body, unbolt the mechatronic or lead frame from the valve body and install the new one. But it does take a bit of experience to not damage anything on the valve body or inside the transmission during the install. You must also have the correct tools and a clean workspace to do the job. If you try to go to the cheap route and just replace an individual sensor, you’ll have to pay the labor charge all over again when one of the other components fail. So if you want to keep your vehicle on the road for as long as possible. And avoid paying more money to fix transmission problems that could have been avoided, you should consider upgrading to a remanufactured TEHCM / Mechatronic from a company like Street Smart Transmission.

All TEHCM/Mechatronic assemblies are located inside of the transmission on the valve body. Objectively, it is a fairly simple repair: simply remove the transmission pan, remove the valve body, unbolt the mechatronic or lead frame from the valve body and install the new one. But it does take a bit of experience to not damage anything on the valve body or inside the transmission during the install. You must also have the correct tools and a clean workspace to do the job. If you try to go to the cheap route and just replace an individual sensor, you’ll have to pay the labor charge all over again when one of the other components fail. So if you want to keep your vehicle on the road for as long as possible. And avoid paying more money to fix transmission problems that could have been avoided, you should consider upgrading to a remanufactured TEHCM / Mechatronic from a company like Street Smart Transmission.

What Transmission Do I Have?

Remanufactured Transmission TEHCM/Mechatronic

The TEHCM/Mechatronic is a complicated little device that sends and receives data from the ECU to the TCM, then distributes actionable commands out to the various components like shift solenoids and pressure switches. It also receives data from the various components, which it then sends back to the TCM and ECU, so it can decide which shift program to use for a given situation. All of this happens along the data bus, which is extremely important to making everything work. That’s why each Street Smart Transmission TEHCM/Mechatronic build starts with a thorough test of the electrical and communications system. If the core fails, it’s either repaired or completely discarded. Next, all of the sensors are replaced with upgraded sensors that can withstand heat, vibration and stress much better than the OE units. All new seals and gaskets are also installed, and each remanufactured mechatronic and remanufactured TEHCM comes with all gaskets, seals and grommets that will be needed for the installation. To learn more about a remanufactured TEHCM or Mechatronic from Street Smart Transmission, click here.